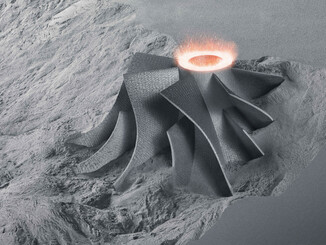

The TruPrint 3000 from Trumpf produces components up to 300 millimeters in diameter and 400 millimeters high using powder bed-based laser melting. The machine can process all weldable materials, such as steel, titanium or aluminium.

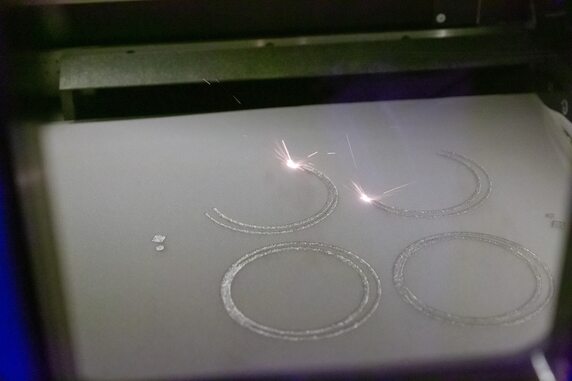

The new TruPrint 3000 is adapted to the quality requirements and production processes in various industries. Central further development: The TruPrint 3000 can now also be equipped with a second laser, which nearly doubles its productivity and significantly reduces parts costs. Two 500 watt lasers operate in parallel throughout the entire installation space of the system.

This makes production significantly faster and more efficient, regardless of the geometry and the number of components produced. Even with large components, a laser can process the complete contour if required. This results in optimum part quality and no seams are created. The Automatic Multilaser Alignment option automatically monitors and calibrates the lasers to each other while the build job is in progress.

Improved protective gas guidance and integrated powder conveyor

The flow concept for the shielding gas is also new. The gas now flows particularly evenly through the system from the rear to the front, thereby increasing the quality of the printed parts. In addition, the new generation of the TruPrint 3000 allows the operator to remove excess powder from the part while still inside the system with the help of an integrated powder conveyor. The excess powder then ends up in a powder container; it can be reused in the next printing process.

The machine and peripheral concept of the new plant prepares the powder “inert”, i.e. under inert gas, if desired. This protects the powder circuit from external influences, resulting in consistent powder quality. In some industries, such as medical technology, this is an important advantage.

Automatic monitoring of the printing process

The new generation TruPrint 3000 now also includes the Melt Pool Monitoring quality assurance system. Special high-speed sensors in the system’s optics automatically monitor the melt pool during the printing process and record the optical fingerprint of the process. The intelligent evaluation software can be trained with a reference construction job and then graphically displays deviations – for example, if the melt pool is too cold or overheated. This enables the machine operator to detect the error, intervene and subsequently analyse it.

Web:

www.trumpf.com