Schmalz is addressing the challenges of industrial automation at Automatica 2023 (June 27 to 30) in Munich. At booth A5.303, the vacuum expert will be presenting innovations – both from the areas of gripping and vacuum generation as well as process-related hardware and software.

© J. Schmalz GmbH

The feeling that Automatica has just been is not deceptive. After just one year, the trade fair operator is once again bringing together the who’s who of the automation industry, thus heralding a new rhythm: From now on, Automatica will take place in odd-numbered years. This change comes in handy for Schmalz, because the vacuum expert has been busy within the past year and has several innovations to present – and it’s not always about the gripper.

With the “Schmalz Solution Kit”, Schmalz leaves the level of components and end effectors. The flexible technology platform combines various software and hardware components to enable robotic cells to see, grip and communicate with higher-level systems more quickly. The key component here is the open bin-picking operating system “ivOS”. It’s not the first product to focus on process. With the “Schmalz Connect Suite”, also part of the trade fair portfolio, intelligent Schmalz products as well as IO-Link components from other manufacturers can be centrally parameterized, managed and analyzed.

From sparking vacuum generators and efficient grippers

A look at the four robot cells at the booth reveals new developments for automated gripping and vacuum generation. For example, the SCTSi compact terminal now also communicates wirelessly with the PLC via IO-Link Wireless. This saves on cabling and reduces the installation effort. In addition, the efficient Compact Pump GCPi with compact valve LQEi and the powerful RECBi are available as purely electric and pneumatic vacuum generators.

© J. Schmalz GmbH

The revised design of the ZLW lightweight layer gripper with its rounded plastic frame is striking. This makes the gripper even more suitable for use in MRC environments. A completely new gripping concept is demonstrated by the technology study of the Schmalz Eco-Gripper. Everyone knows the “suction cup” principle – only Schmalz backs it up: sensors monitor the vacuum, and a small vacuum generator kicks in if a leak occurs. With smooth, absorbent surfaces, the energy requirement is therefore zero.

The new FEL area gripper is a specialist for screen production. It is used where space is limited and the gripper must be as low-profile as possible. Another highlight is the integrated gripper segmentation. This allows individual zones to be switched on and controlled.

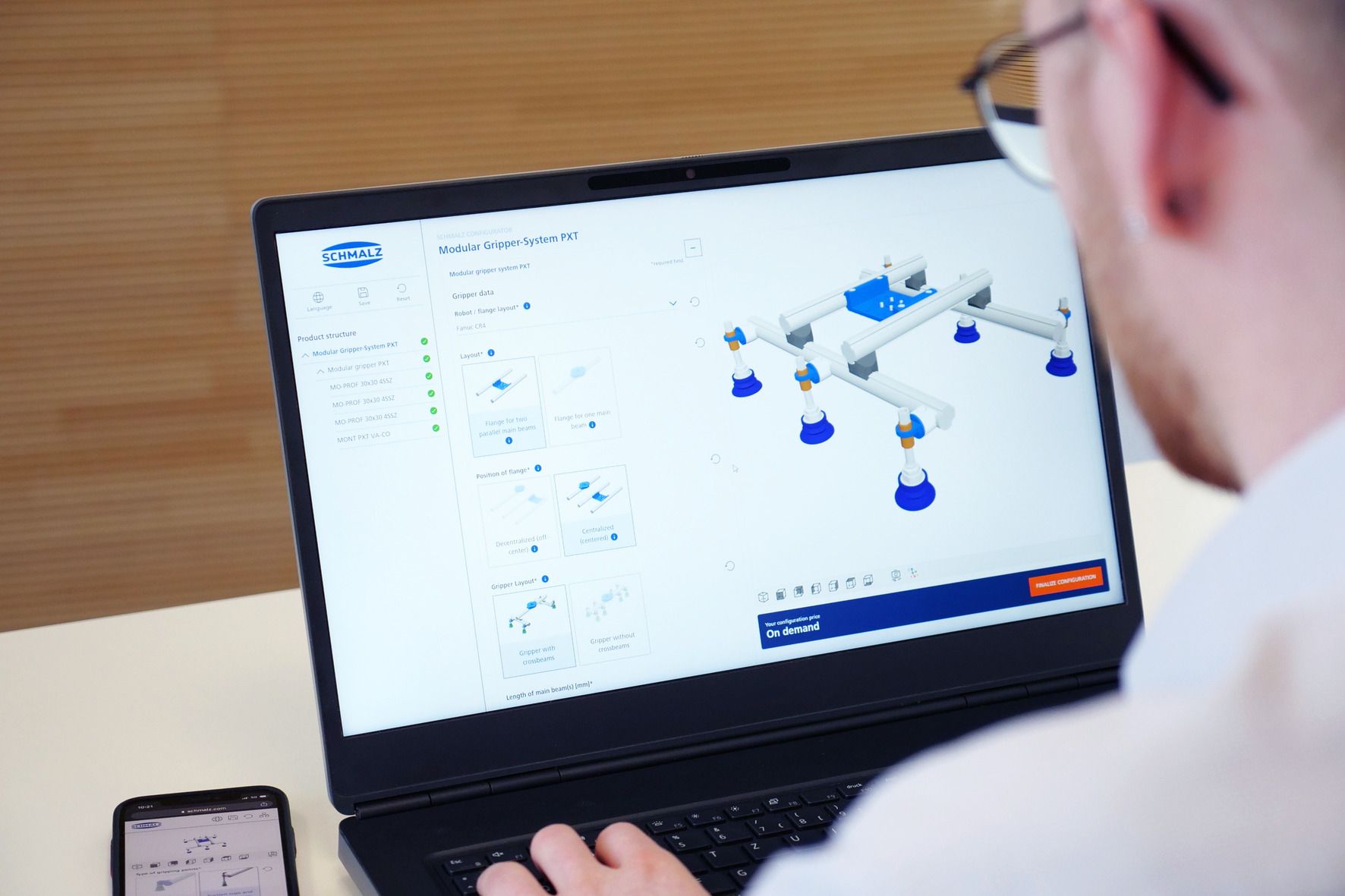

The highlight of the digital services is the new PXT configurator. The modular gripper system is predestined for different and changing handling tasks due to its modular concept. Now users can configure a gripper themselves from various components – and receive their flexible, high-quality gripper even faster.

Digital in manual

Even though Automatica focuses on the key technologies of industrial automation, Schmalz also presents new products for manual handling. Because here, too, digitalization is leaving its mark – in the form of the Schmalz Application Assistant on the JumboFlex or the digital product file.

Background

Schmalz is one of the market leaders in automation with vacuum as well as for ergonomic handling systems. The products of the internationally positioned company are used in logistics applications as well as in the automotive industry, the electronics sector or furniture production.

The broad spectrum in the Vacuum Automation business area includes individual components such as suction pads or vacuum generators, complete gripping systems and clamping solutions for holding workpieces. In the Handling business segment, Schmalz offers innovative handling solutions for industry and trade with vacuum lifters and crane systems. With the Energy Storage business area, the company is establishing a further mainstay in the field of stationary energy storage.

The combination of comprehensive consulting, high innovation orientation and first-class quality ensures customers sustainable added value. Intelligent solutions from Schmalz make production and logistics processes more flexible and efficient – and at the same time fit for advancing digitalization.

Schmalz is represented in all major markets with its own sites and trading partners in around 70 countries. The family-owned company employs around 1,800 people at its German headquarters (Glatten, Black Forest) and in 28 other companies worldwide.

Web:

www.schmalz.com