In the course of Industry 4.0 and the smart factory, intelligent systems independently control their own production process. The goal is to maximize operational efficiency by automating as much as possible. Fluid management should also be taken into account in automation projects to avoid deviations and associated production downtime. And this is exactly where the experts from Zeller+Gmelin and Hydac come in: With the help of the newly developed fluid management system “ZG Fluid-Check Pro”, the cooling lubricant supply can be automatically monitored, organized and controlled.One of the first practical users for the newly developed system is Heron CNCTechnik from Vorarlberg.

© Zeller+Gmelin

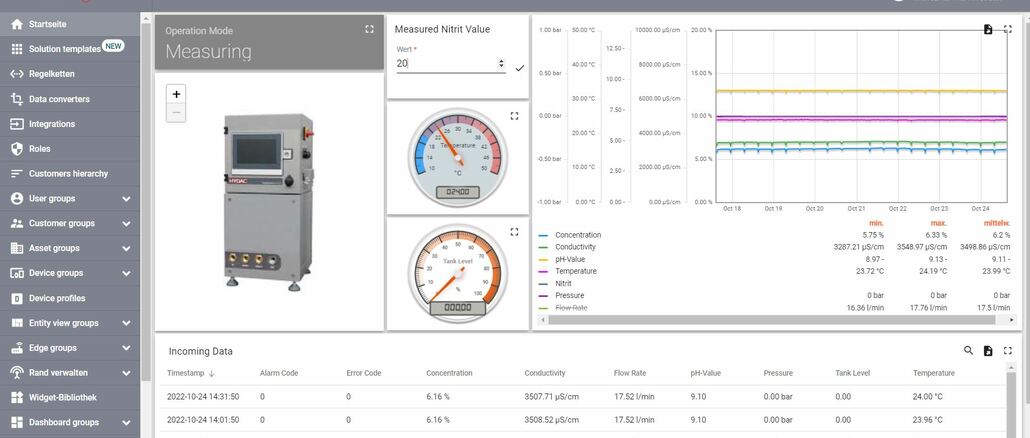

The smart device ZG Fluid-Check Pro monitors the level and measures concentration, pH, conductivity and temperature in real time – every minute the current measured values are displayed on the dashboard. In addition, four further values such as nitrite or, for example, the tramp oil content can be entered manually.

In case of deviations from the target concentration, readjustments are made automatically. It is also possible to store coolant profiles, whereby the top ten of the most common water-miscible coolants from Zeller+Gmelin are already stored, so that the user only has to select his preferred product on the display, without having to enter any additional parameters.

Two metering pumps can be connected for the automatic addition of actuators/inhibitors. Together with a multiplexer, one system monitors up to seven CNC machines.

“Our fluid management system permanently records the emulsion status, so that traceability is also guaranteed,” emphasizes Thorsten Wechmann, Strategic Business Unit Manager at Eislingen-based lubricant manufacturer Zeller+Gmelin. As an independent company within the family-run Heron Innovations Factory, Heron CNC-Technik GmbH specializes entirely in metal and plastics processing.

As a contract manufacturer for milling and turning, Heron uses state-of-the-art CNC machining centers to produce prototypes as well as series parts in batch sizes ranging from 1 to 10,000. The customers come from a wide range of industries, such as medical technology, special machine construction, automotive or semiconductor technology.

“We want to meet the demands of increasing competition and a growing clientele, which is why we are focusing on end-to-end, automated processes entirely in line with Industry 4.0,” is how Manuel Gmeiner, the business manager there, sums it up. “Most of our machines run fully automated, around the clock, 365 days a year.”

Manufacturing processes and techniques are constantly being developed further. One hurdle to ‘unmanned’ production, however, is cooling lubricant management. Levels would have to be checked regularly and refilled manually – even on holidays or weekends.

“The failure of the lubrication could not only mean the complete standstill of the machine, but could also cause damage,” Heron Managing Director Manuel Gmeiner gives food for thought.

© Zeller+Gmelin

Digital factory: Maintenance is often forgotten

And Thorsten Wechmann from Zeller+Gmelin poses the question in the direction of the Smart Factory: “What use is the simulation of production and the elimination of interference contours in the machining process if an employee has to intervene at the machine at the end because the filling level or other parameters of the cooling lubricant are not correct? Self-organizing production always includes the ability to take timely and automated countermeasures when deviations from defined values occur. A deviation in the cooling lubricant must not become the eye of the needle.”

Although solutions already exist today with which current lubricant values or key figures can be transmitted to the smartphone via SMS, “If there is a deviation, someone still has to readjust manually,” Thorsten Wechmann continues. Smart monitoring for SMEs “In order for a medium-sized company to ensure its own competitiveness in the long term, there is often no way around a high degree of automation and the associated digitization of processes,” emphasizes Philipp Götz, Product Manager at Hydac Filter Systems GmbH: “Our goal is to support manufacturing companies on their way to Industry 4.0. With the ZG FuidCheck, we have developed a compact device that can not only monitor the entire cooling lubricant cycle of up to seven machines as well as central systems simultaneously, but also intervene independently and in a regulating manner in the event of deviations.”

Fluid management from Eislingen

In Zeller+Gmelin, the company has also found the right cooperation partner. As a long-standing supplier of water-miscible cooling lubricants, which are available from Zeller+Gmelin under the brand name Zubora for machining production. With ZG Fluidmanagement GmbH, a separate subsidiary was even founded for this purpose. “Many modern companies now rely on effective fluid management, which is essentially based on the analysis and conditioning of liquid working media as well as accurate consumption recording and evaluation. The aim is to increase efficiency by, among other things, maintaining the target concentration and preventing underconcentration. This also results in longer tool life and better surface qualities in the machining process,” Thorsten Wechmann knows from numerous practical applications.

But too high a concentration also has negative effects: On the one hand, more lubricant is consumed, on the other hand, the foaming behavior of a cooling lubricant can change. If all parameters are always optimally set, the lubricant can be used for a significantly longer time and in a process-safe manner.

“Of course, we are also permanently concerned with the question of how lubricant management can be further optimized.” In terms of fluid management systems, the market still offers a lot of room for improvement. Many devices are not able to flush. As a result, they become inaccurate and have to be constantly readjusted – not so the ZG Fluid-Check. The device is also very compact and fits into any production. “The very first projects were successful and we were able to benefit from each other’s experience and pass it on to the user. Our customers can now purchase the system through our Fluid Management business unit, of course in combination with our own skin- and resource-friendly Zubora high-performance cooling lubricants.”

And Phillip Götz from Hydac adds: “Medium-sized industrial customers in particular want an ‘all-round carefree package’ from their lubricant suppliers so that they have time internally for their core business. With the sale of our devices, Zeller+Gmelin is also targeting its offer specifically at companies that want to manufacture with high automation but do not want to provide additional resources in terms of fluid management. The machine operator then no longer has to remeasure, refill or readjust at the machine. That’s a huge time savings, which means more time for value-added tasks.”

© Zeller+Gmelin

High-precision prototypes and series parts in machining technology

Manuel Gmeiner from Heron agrees: “The cooperation with Zeller+Gmelin and Hydac is another important building block for us towards the complete digitalization of our production.

The ZG Fluid-Check is currently being tested on a fully automated Hermle system in which a robot system equips three five-axis milling centers. The system is connected to an autonomous transport robot system from Servus Intralogistics, another Heron Innovations Factory company. “This allows the plant to be fully automated 24/7.”

After a successful trial phase together with Zeller+Gmelin, Heron had decided on two of the units with multiplexers, to which 14 machines can be connected and supplied.

Digital, intuitive and user-friendly

In addition to the level, the device continuously measures the concentration, as well as the pH value and other parameters. To keep the concentration at the desired level, the dosing pump counteracts in time if necessary. This also prevents any risks that could be associated with under/over concentration, such as foaming or corrosion protection impairment.

“The values can either be read directly on the touch panel from the device or also from outside – for example on a PC or via tablet. A user-friendly dashboard clearly summarizes all the information so that it can also be presented in a maintenance meeting, for example, or is permanently available to the personnel, even without them being directly in front of the plant,” explains Phillip Götz.

© Zeller+Gmelin

Multiplexer for seven machines simultaneously

There are currently two devices in use at Heron. Later, the solution will be extended to eleven additional machining centers. The experts around Manuel Gmeiner then want to additionally test the multiplexer, which allows up to seven machines to be monitored simultaneously. “The multiplexer ensures continuous monitoring and readjustment of the cooling lubricant concentration and is particularly suitable when several individually filled, robot-controlled systems are in use, as is the case with Heron,” specifies Philipp Götz. And Markus Müller from ZG Fluidmanagement adds: “Our employees are specially trained for such installations so that we can offer the most comprehensive support and service possible for this.”

“The system is extremely smart and will pay for itself quickly,” concludes Heron’s Managing Director Manuel Gmeiner. “Lubricant is now not only automatically replenished in the correct concentration, but additional measured values are also supplied. This means we can permanently monitor the concentration of our lubricant, which has significantly improved reliability. We also no longer have to continuously check manually, so our colleagues can concentrate on their actual activities.”

After the ZG-Fluid-Check Pro proved itself in practice right from the start, an extension for multi-machine supply is already planned for 2023: the ZG-Fluid-Check Neo can connect several machines at once by means of a ring line and ensure efficient fluid management.

Web:

www.zeller-gmelin.de