The 16th Blechexpo in Stuttgart showcased the entire process chain of cold-forming sheet metal processing and the associated thermal or mechanical cutting, joining and bonding technologies. Of course, Bruderer and its stamping technology were not to be missed, especially as this year is a very special one in the company’s 80-year history.

© Bruderer

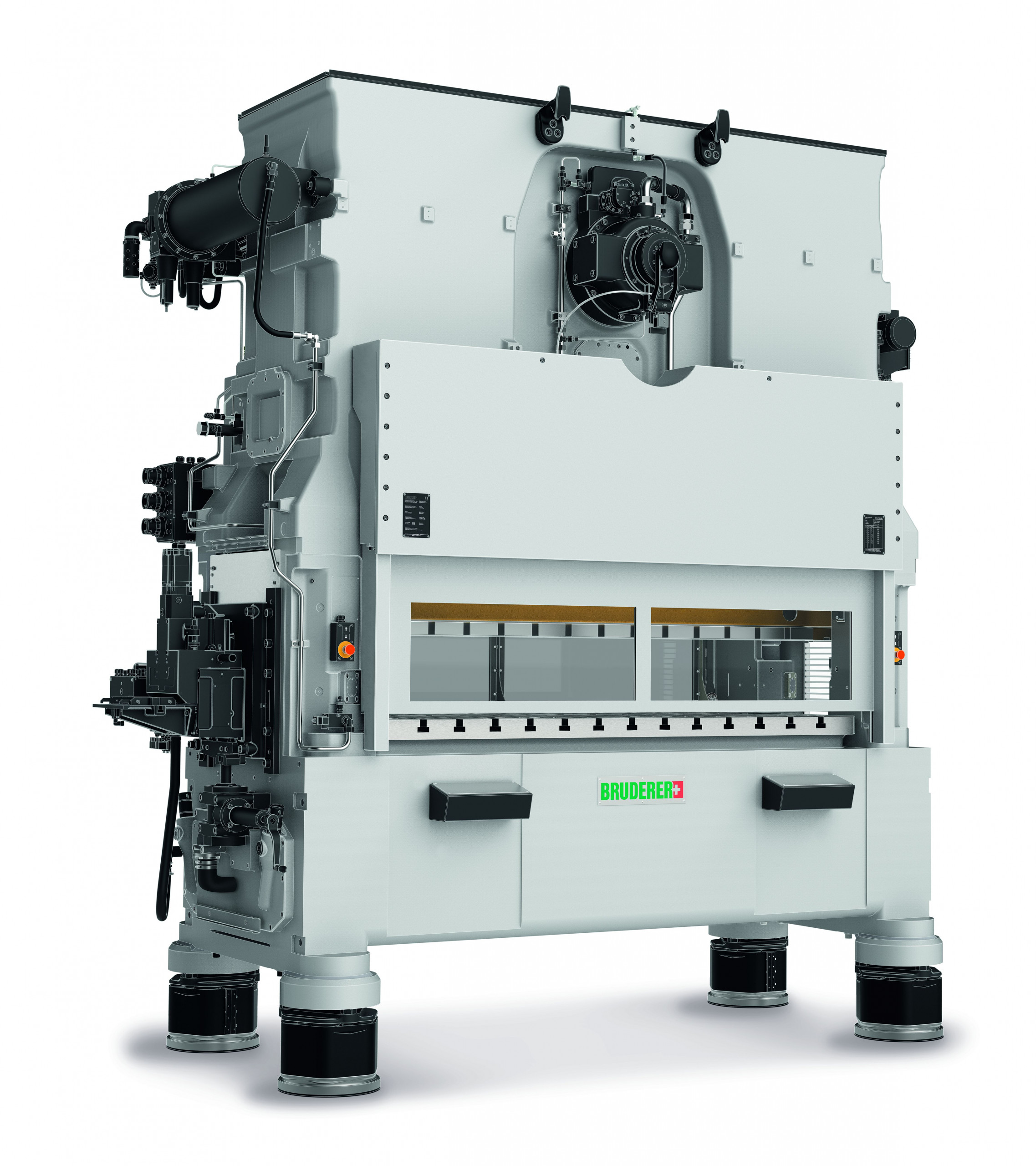

Among other things, the latest member of the Bruderer family of automatic punching presses will be celebrating its world premiere. With the BSTL 350-88, Bruderer presents a completely new development in automatic punching presses, based on the technology of the BSTA series. Under the motto “Reduced to the essentials”, a new automatic punching press was developed to meet the needs of customers in the 3C market who produce small parts in high volumes. As a fixed-stroke automatic punching press, the BSTL shows its strengths when it comes to precision and continuity. Compared to older machine models, it consumes up to 30 percent less energy.

It is operated via a user-friendly, customizable interface with a new tile look. The customer can access the control system with various devices via a web browser. Remote maintenance is state-of-the-art and offers the highest level of cyber security.

The BSTL is offered complete with a servo feed of the latest generation. This makes it suitable for use in a wide range of industries, such as communications, consumer electronics, computer electronics, automotive and industrial and household appliance applications.

The BSTL is offered at an “extremely interesting price-performance ratio”, according to the manufacturer, thanks to its completely new focus on these areas of application. Delivery will take place from spring 2024.

© Bruderer

“More space for more productivity.” This was taken literally with the new BSTA 710-220. With the world’s longest bed in its performance class, according to the manufacturer, it creates plenty of space for precise and productive work. Thanks to the automatic stroke adjustment and various options such as different stroke and tool installation heights, press force monitoring, etc., the BSTA 710-220 can be adapted to individual customer requirements and used in a variety of ways, for example for rotor/stator and transformer laminations, in environmental technology, for connectors, industrial applications, semiconductors and transistors and telecommunications.

According to Bruderer, the precise mechanics and the special Bruderer drive and lever system make the BSTA a long-lasting and valuable investment. Delivery will take place from summer 2024.

Web:

www.bruderer.com