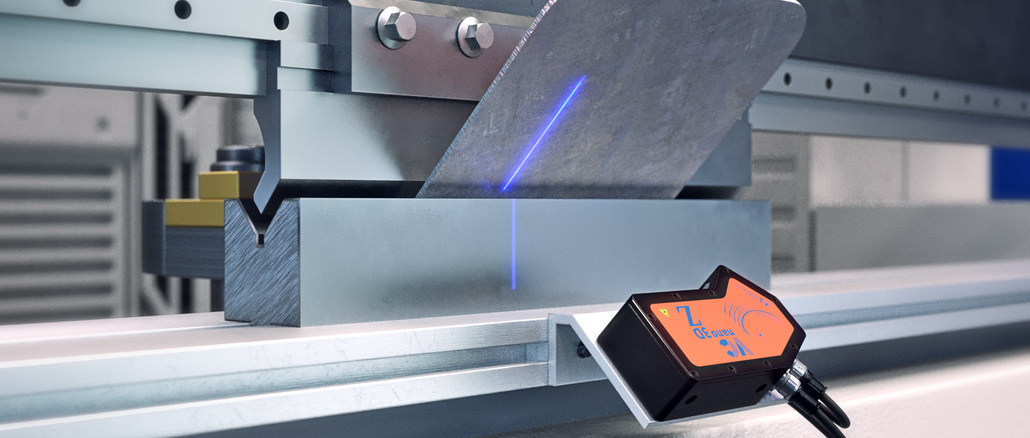

Vision Components will showcase its field-proven laser profile sensor for angle measurement and inline readjustment in sheet metal bending at EuroBlech.

The VC nano3D-Z laser triangulation sensor operates autonomously, without an external computing unit, and is already fully calibrated for angular accuracy testing. It allows dynamic closed-loop control of the contact pressure, thereby increasing throughput and efficiency. The measurement resolution is better ± 0.05°. The intelligent sensor can be easily mounted on press brakes and connected to any control/PLC and directly outputs the workpiece angle in degrees. In controls from Delem and – new – Cybelec, the sensor is already stored as standard. Also new are a mounting kit and other accessories for easy commissioning.

The IP67 laser profile sensor is suitable for die widths from V6 to V200 and die heights from 55 mm to 150 mm. Versions for larger dies are also available on request. The sensor delivers robust results even with shiny or brushed metals as well as perforated sheet metal. The German manufacturer Vision Components has developed it specifically as an OEM product and, in addition to the complete turnkey solution, also offers a construction kit for individual further development. The integrated embedded vision system and the blue high-power class 2 laser are matched to each other.

Web:

www.vision-components.com

Euroblech Hall 12, Booth A02