Among other things, Yamazaki Mazak presented a new laser cutting machine, the Optiplex 3015 Ez, at Euroblech. According to the manufacturer, it offers cutting-edge technology for high-precision laser cutting at an economical price.

Mazak will also use the exhibition to present itself as a provider of end-to-end manufacturing solutions, demonstrating high-performance, high-precision laser cutting on large material thicknesses.

The aim is to show how the synergy between the laser cutting machines offered by the company and conventional machine tools can help customers to work more productively and profitably.  With the launch of the Optiplex 3015 Ez, Yamazaki Mazak is offering its customers ease of use and performance at an affordable price.

With the launch of the Optiplex 3015 Ez, Yamazaki Mazak is offering its customers ease of use and performance at an affordable price.

This follows the company’s self-imposed commitment to deliver innovative solutions that meet the increasing demands of the manufacturing industry.

These machines are designed for a wide range of materials and material thicknesses and offer enormous precision, high mechanical rigidity and unparalleled reliability, says Mazak.

Intelligent functions provide the user with efficient assistance and protective measures to minimize set-up times and optimize productivity.

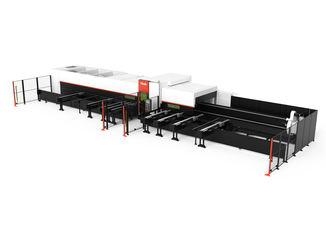

The 6 kW machine on display at Euroblech is part of a fully integrated production cell in which the workpiece passes through all the necessary processes from the blank to the finished part.

In addition to the Optiplex Ez, which is equipped with a triple pallet changer to optimize the cycle time, the cell includes a Mazak CST 3015 storage automation system with eight storage compartments: six for loading new material and two for unloading sheet remnants.

It also has a robotic sorting system – the Mazak Smart Manufacturing Cell – for separating out the finished parts and placing them on a pallet ready for the next process.

The individual components of the cell are coordinated centrally by the new Smooth Line Controller software.

The Smooth Line Controller app integrated into the CNC enables comprehensive process integration, incorporating all processes, from incoming orders and the transfer of the program from the CAD-CAM department, through material management, laser cutting and sorting, to the feedback of the finished parts.

The system can not only be used for production planning, but can also feed critical production data back to the ERP system.

Mazak’s latest laser cutting machine with fiber laser, the Optiplex 3015 Neo, will also be on display at Euroblech.

The 20 kW machine on display belongs to the Mazak Neo series.

This is the name given to high-performance machines that are characterized by “outstanding productivity and precision”, as the manufacturer promises, but also have “one of the highest levels of environmental compatibility of all machines in the relevant performance class”.

The machine’s working area enables cutting of sheets up to 1525 mm x 3050 mm in size using a new 20 kW fiber laser resonator.

Thanks to the high-power laser source and new Grand Cut technology, the machine delivers maximum accuracy and stable cutting properties on thick sheets.

One of the outstanding features of the machine is Mazak’s beam shaping technology, which, supplemented by the beam diameter control in the MCT3 multi-control cutting head, ensures an enormous increase in production and superior cutting quality when cutting sheet metal.

By adjusting the beam shape, operators are now able to cut sheets up to 50 mm thick with up to four times the stability of conventional laser cutting.

The beam shaping can also improve the angular deviation of the cut edge by more than 80 percent compared to conventional machines, resulting in a significantly higher cutting quality. Visitors to the Mazak stand will be able to see for themselves the innovative beam forming and Grand Cut technologies and the cutting quality from Mazak by means of live demonstrations and the cut sample workpieces.

© Mazak