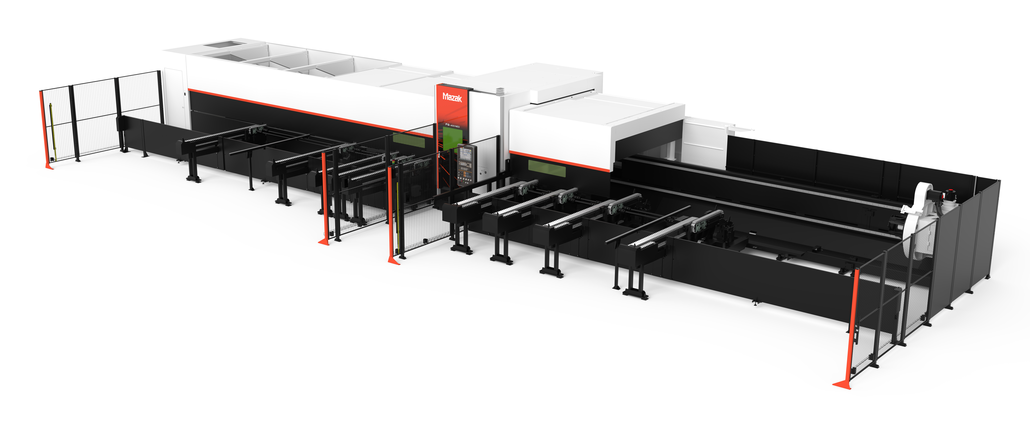

The FG-400 Neo is a universal solution designed for maximum productivity and ease of operation, says manufacturer Mazak. The new machine model has been optimized with a view to cutting tubes and long section steel.

With its resonator with beam mode adjustment, this newly designed machine can combine a wide variety of cutting processes, including 3D cutting, tapping, drilling, chamfering and flow drilling. Beam shaping technology concentrates beam density where needed and provides higher cutting speed and quality on an enormous variety of materials. The laser beam generated via fiber lasers has a shorter wavelength than the beam of a CO2 laser. The fiber laser is thus significantly more effective in laser cutting, not least on materials that are difficult to machine.

A wider range of applications

The FG-400 Neo has been specially designed for cutting large pipes – whether round, square or rectangular – as well as for wide flange, double T and angle beams. The new machine model is also suitable for cutting highly reflective materials such as copper and brass, as well as complex contours and tube joints with tight fits.

All this is made possible by innovative Mazak features aimed at achieving the highest cutting quality and accuracy. These include the 3D cutting head, which can be moved in the A and B axes and enables machining of a wider range of materials at the desired angle and with maximum accuracy. Damage can be avoided by deflecting the 3D cutting head in the event of a collision with the workpiece.

The clamping system consists of four interacting chucks that move simultaneously on the axes and rotate around them, eliminating material deformation. In this way, a stable cutting process on materials of different thicknesses and an increase in productivity are achieved while reducing material waste.

Other features include automatic centering and clamping of the material, as well as supports to accommodate differently shaped material and protect against material sagging during cutting. The machine is offered in different versions with loading and unloading units for 6 m, 8 m, 12 m and 15 m.

Thanks to significant improvements, the FG-400 Neo enables shorter cutting times. For example, a 33% faster cutting process is achieved on square tubes and wide flange beams made of mild steel when oxygen is used as an auxiliary gas, while on square tubes made of structural and stainless steel the cutting process can be accelerated by up to 43 and 49 percent respectively when nitrogen is used as an auxiliary gas.

The fiber laser resonator also significantly lowers operating costs and reduces the impact on the environment – with power savings of up to 40 percent during both cutting and standby operation. Fiber laser technology also does not require any laser gas at all.

Even easier operation and optimum maintenance access

Operator friendliness has traditionally been at the forefront of machine development for Mazak, so special emphasis is also placed on maintenance access and operation. The machine is equipped with FX CNC with 15″ screen and is operated with FX Tube CAD-CAM tube cutting software. This provides a wide variety of functions – such as parts nesting, simulation tool and scheduling function – to achieve continuous production. By cleverly combining all these elements, setup times are shortened and operating errors are reduced at the same time. The bottom line is significantly higher productivity.

The FG-400 Neo offers unobstructed access and excellent visibility of the cutting area and high operator friendliness. The ergonomic design of the FG-400 Neo facilitates the operator’s work by placing the control unit and the charging and discharging stations on the same side. This offers the further advantage that the machine can be placed directly against the wall, thus saving considerable space.

According to Mazak, the machine owes its “exceptionally high productivity” to the fiber laser resonator in combination with the integration of different processes on one and the same machine. This makes the FG-400 Neo the ultimate solution for volume manufacturers who want to move into new dimensions in terms of laser cutting with tube lasers, Mazak promises.

Founded in 1919 in Nagoya, Japan, Yamazaki Mazak is now an international company specializing in the manufacture of laser cutting technology, machine tools and machining centers. Since entering laser cutting technology in the 1980s, Mazak has established itself as a global leader, continually adding new, groundbreaking technology to its machines. These include fiber lasers, direct diode lasers (DDL) and 3D cutting technology for cutting large tubes and profiles as well as sheet metal.

Web:

www.mazak.de