From production with electrolysers to the refueling process at the hydrogen filling station: Pilz is presenting its automation solutions from the areas of functional safety and industrial security at Hydrogen + Fuel Cells Europe. They enable the safe monitoring and control of processes along the entire hydrogen value chain. The trade exhibition will take place from March 31 to April 4, 2025 as part of the Hannover Messe.

Detecting gas leaks reliably and quickly, keeping a constant eye on pressure, filling level, voltage and current, safely monitoring combustion processes – proven safety principles in automation can protect hydrogen applications particularly economically and intelligently.

At Hydrogen + Fuel Cells Europe, Pilz is presenting its solutions for functional safety in the hydrogen industry. The automation company will also be presenting how hydrogen applications are protected against tampering and incorrect operation.

Functional safety for the hydrogen industry

The safety solutions from Pilz help to always view safety as an overarching monitoring function of components and their functional relationship in the process chain. They therefore offer added value for the entire hydrogen value chain.

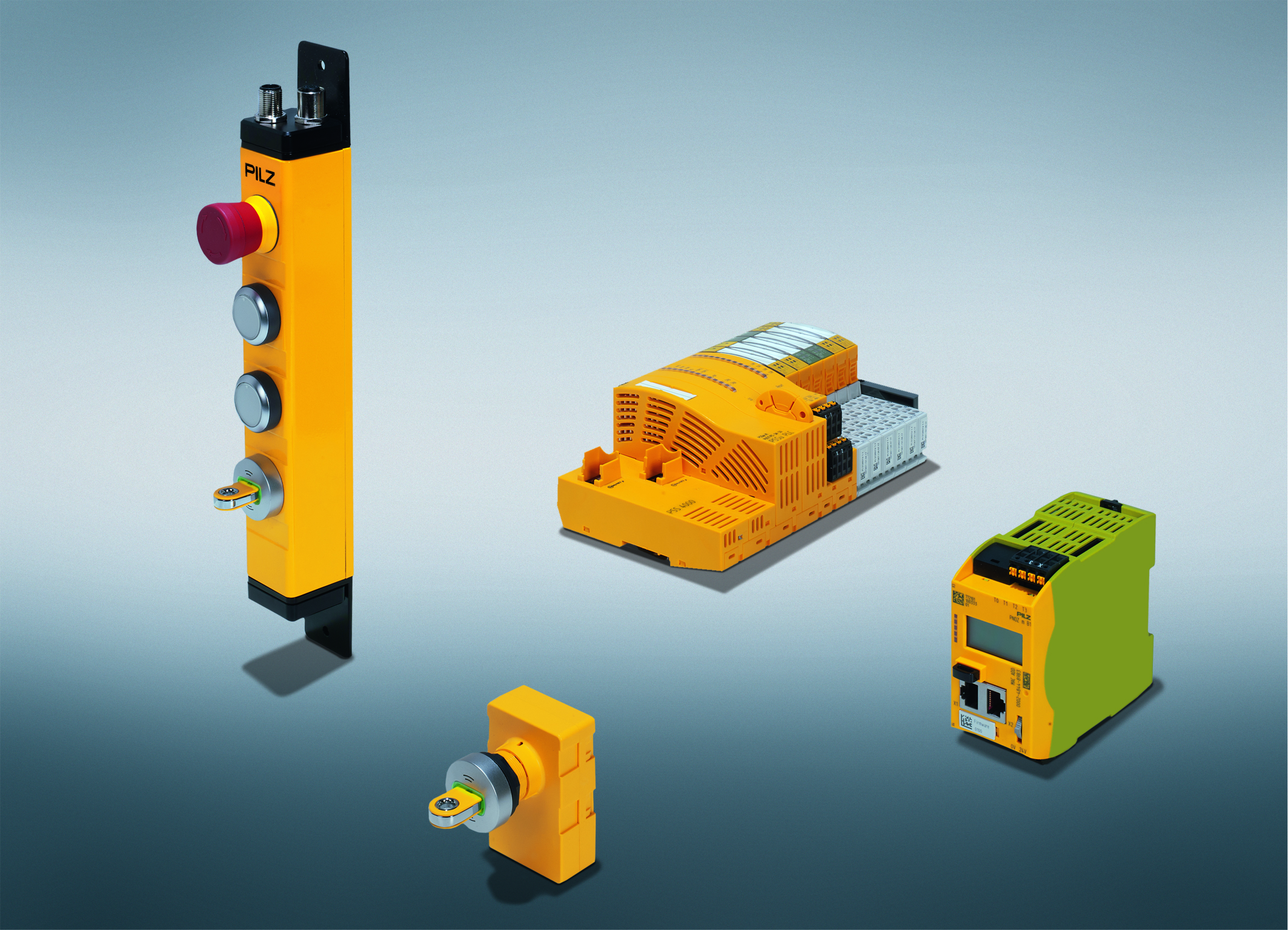

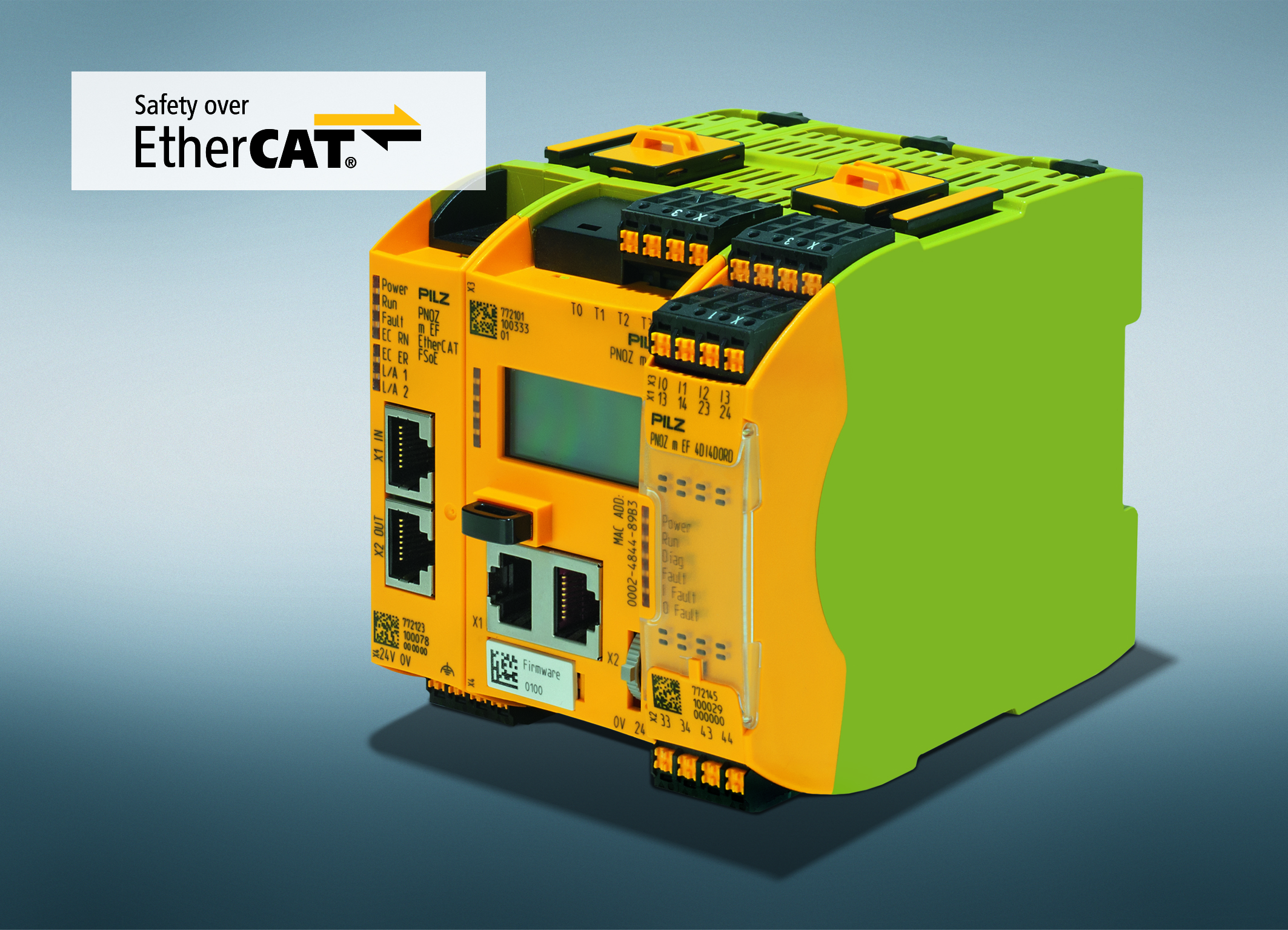

From the electrolysis process to steam reforming – the Pilz experts on the stand will explain the different safety-related approaches that are important depending on the type of hydrogen production. For example, the Pilz small controller PNOZmulti 2 and the automation system PSS 4000 from Pilz ensure the production of hydrogen using the electrolysis process. The automation system PSS 4000 has also already proved its worth in keeping an eye on all safety functions at hydrogen filling stations – in the cooling system and the high-pressure storage tanks, as well as when dispensing hydrogen.

A holistic approach to safety and security

In addition to functional safety, a holistic view of safety also includes industrial security, i.e. protection against manipulation and incorrect operation. Industrial security plays a special role, not least due to the requirements of NIS2 (EU Directive on Network and Information Security) – mandatory from 2024 – and the new Machinery Directive, which will be mandatory from 2027.

From user authentication, data and network security, functionally safe operating mode selection to access management or electronic maintenance protection: Pilz’s experts will be on hand at the stand to provide advice on the automation expert’s tailored security solutions.

Mushroom experts at the forum

Safe automation is also a topic in the accompanying lecture program at the trade fair:

At the Public Forum, Albert Cot, Market Development Engineer at Pilz, will report on the challenge of implementing functional safety and industrial security in hydrogen applications.

In the Technical Forum, Thomas Braasch, Sales Engineer at Pilz, goes into more detail about the importance of functional safety and industrial security in the production of hydrogen using the electrolysis process.

Canada’s automation – green, digital and sustainable

Under the motto “The future’s here”, Canada is showcasing its industrial strengths in areas such as automation, energy, digital transformation and green technologies. Pilz is active in Canada with a subsidiary in Mississauga, Ontario, and is helping to shape the industrial transformation for a green, digital and sustainable future in Canada.

Web:

www.pilz.com