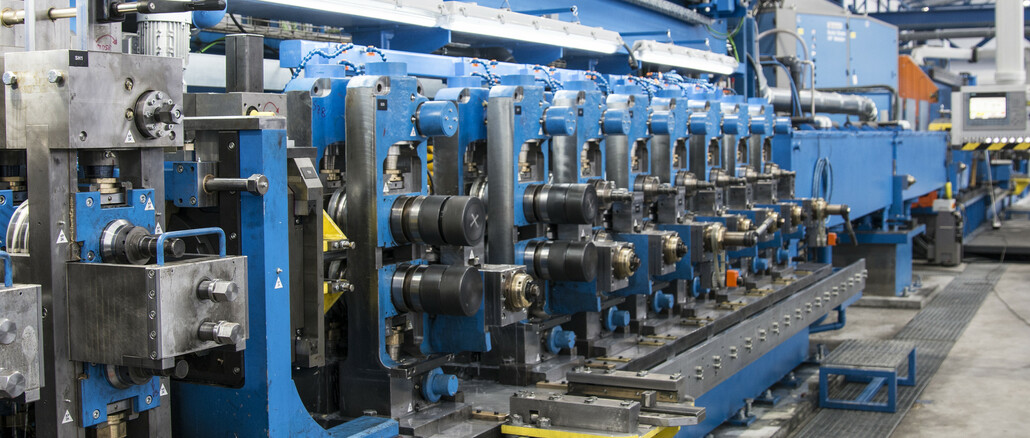

Bornay SL (Bornay), headquartered in the Spanish town of Ibi, has successfully commissioned a high-frequency pipe welding line type RD 40 from SMS Group.

The new pipe welding line enables Bornay to manufacture high-quality pipes with round, square or rectangular cross-sections at yield strengths of up to 1,200 MPa. This makes it possible to produce tubes with diameters between 10 and 40 millimeters and wall thicknesses of up to 4.5 millimeters.

Tubes with a square cross-section are manufactured in dimensions up to 30 x 30 millimetres as well as rectangular products up to 40 x 20 millimetres with wall thicknesses of maximum 4.00 millimetres.

The products are used as precision tubes in the automotive industry, but also for furniture, in agricultural sectors and for the structures of solar tracking devices. The manufacture of these pipes requires a high degree of precision, which is why Bornay placed high demands on the new pipe welding system from the outset. Thanks to the close cooperation between the two companies, this was successfully put into operation despite the difficult conditions triggered by the Covid 19 pandemic.

SMS Group is a group of internationally active companies in plant and mechanical engineering for the steel and non-ferrous metals industry. Around 14,000 employees worldwide generate sales of more than EUR 2.9 billion. The sole owner of Holding SMS GmbH is the Weiss family foundation. The plant in the Alicante region of Spain has been producing welded steel pipes for various industries since 1965.