Trumpf has launched a new generation of its TruBend Cell 5000 automatic bending cell. The cell can be programmed with the TecZone Bend software. Bending programs can be generated within seconds and small batch sizes can be produced even more economically.

In addition to the manual Trumpf bending machines, the TruBend Cell 5000 now also has the new TecZone Bend programming software. With their help, parts can be programmed within a few seconds, usually without manual intervention. If required, the software can even process several parts simultaneously. It calculates the optimum bending sequence, the optimum arrangement of the tools and the robot path fully automatically and ensures that collisions are avoided during the entire process.

TecZone Bend breaks down assemblies into individual parts with a single click. The programming system even generates a suggestion for picking up the blanks and stacking finished parts. However, users can manually adjust the proposal at any time. Fast programming thus makes a significant contribution to being able to manufacture even the smallest batch sizes economically and automatically. Clever automatisms relieve the programmer of tedious standard tasks, which also increases quality.

© Trump

Quiet, energy-saving, precise and highly productive

The new TruBend Cell 5000 is available with bending machines from the current TruBend Series 5000. Their drive is highly dynamic and precise, but at the same time particularly quiet and energy-efficient. Compared to a classic hydraulic drive, it not only saves up to 50 percent energy, but also increases the productivity of the cell.

A back gauge system ensures that the blanks are precisely positioned in the machine during the bending process. With the aid of a laser, an angle measuring system checks the bending angles automatically and independently of the tool used. If necessary, it readjusts.

Proven functions also with new generation

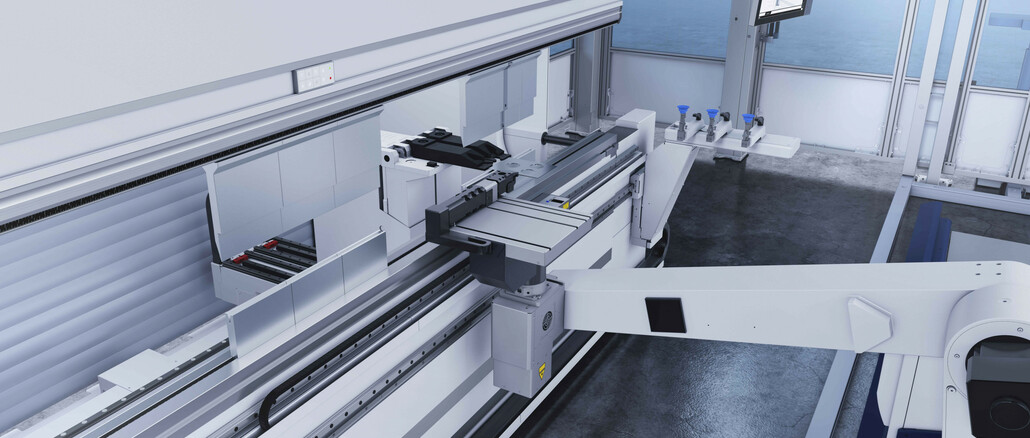

The new generation of the TruBend Cell 5000 is equipped with many automation components. The bending process, for example, is performed by the BendMaster. Trumpf has developed this robot especially for automated bending. It is available with a load capacity of 150 kilograms or 60 kilograms.

The BendMaster can be automatically equipped with various grippers, with which it can transport blanks up to four meters long from a stack to the machine. The robot automatically detects parts with a newly developed digital sensor and thus picks up the sheets correctly. Depending on the size, he grips blanks with the help of pliers or vacuum suction cups.

Double sheet detection ensures that it only lifts one sheet at a time. If the bending cell is connected to a storage system, the BendMaster fetches the raw material directly from the storage cart. He can sort finished parts into boxes, or place them on pallets and conveyors.