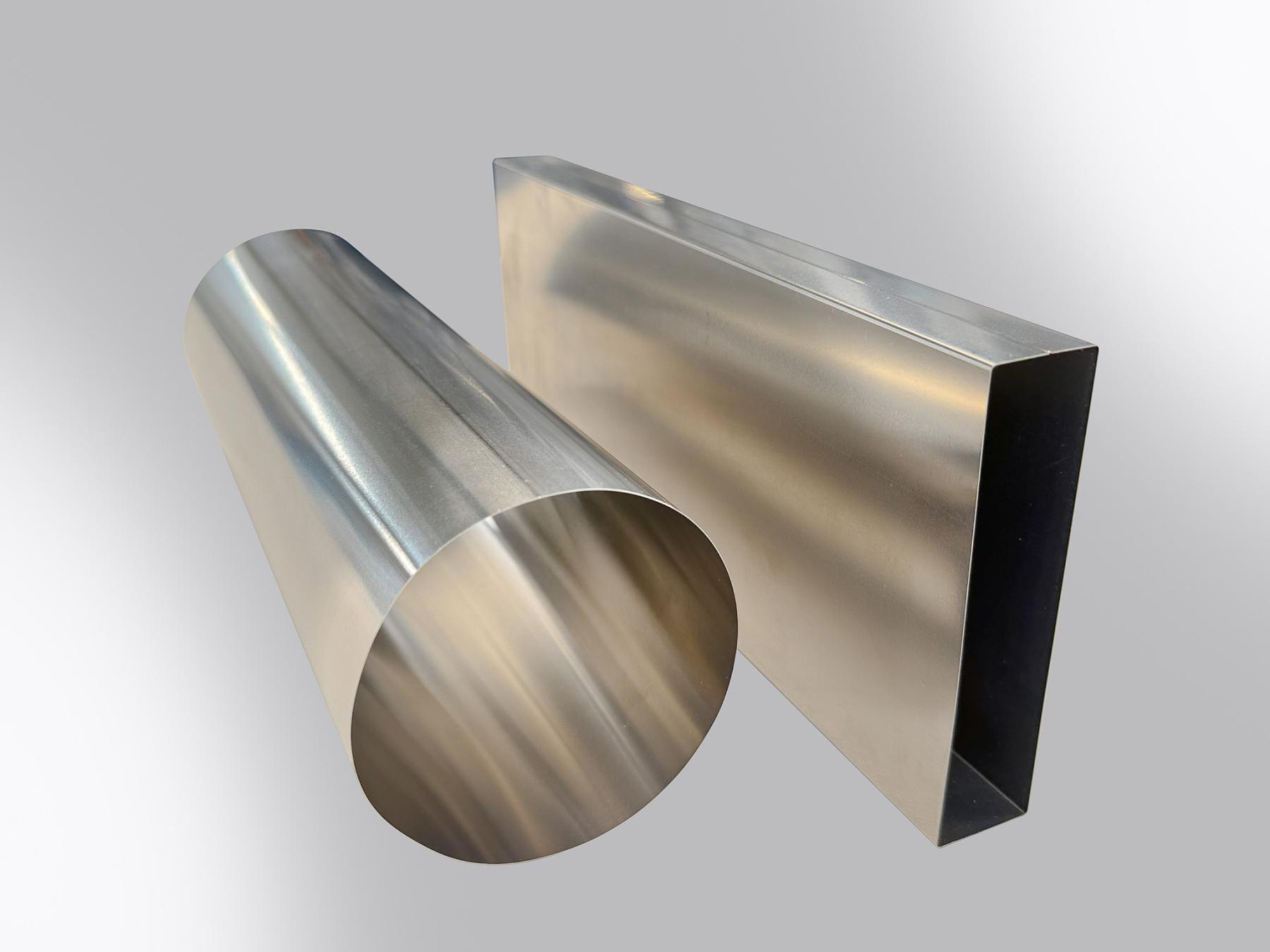

Weil Technology offers fully automated solutions for the production of laser-welded tubes from coil, including roll bending, longitudinal seam welding and finishing of the tube ends. With a complete process chain and thanks to decades of experience, the developers enable efficient and flexible production of high-quality laser-welded tubes according to individual customer requirements.

© Weil Technology

This also applies to the production of water storage tanks: With fully automated welding process solutions developed by Weil, high-quality pressure vessels such as stainless steel boilers with heat exchangers, water storage tanks made of stainless steel or black plate as well as thin-walled pipes with wall thicknesses of up to 3.5 mm are produced efficiently. Longer prismatic cell cups are usually produced by continuous profiling or intermittent press profiling. Weil Technology now offers an alternative fast process with a compact system that enables stainless steel cell cups with a wall thickness of just 0.15 mm.

The Schaal Technology team will be providing information about the versatile systems for forming and punching all materials, from paper to spring steel. The main areas of application are in the e-mobility, electrical industry and medical technology markets. Third in the group is Novatec from Italy.

Web:

weil-technology.com

schaal-technology.com

novatecengineering.it