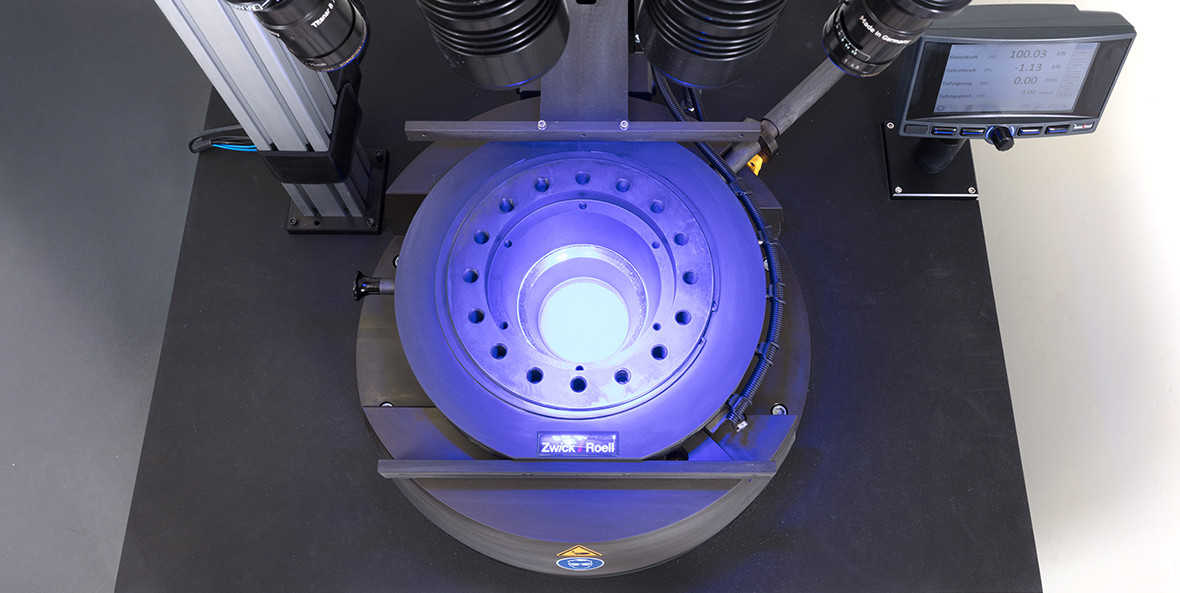

With the testing system for sheet metal forming tests (BUP) with test loads of 400 to 600 KN, ZwickRoell is launching the world’s first automated complete solution on the market. The testing system is particularly suitable for industrial use in sectors such as the automotive and aerospace industries, where high-precision sheet metal components are essential.

The new testing system improves efficiency and precision in sheet metal forming and simplifies quality testing processes. Equipped with a 6-axis industrial robot, specimen identification via 2D code and the high-precision VideoXtens measuring system, the BUP can be used for hole expansion tests, for example.

“The introduction of automated sheet metal forming testing is a significant advance in materials testing technology. Automation not only allows our customers to speed up their production processes considerably, but also to increase the precision and reliable reproducibility of the tests, as they are independent of operator influence. This significantly reduces rejects and material waste. Ultimately, this enables our customers to produce more cost-efficiently and at the same time ensure the quality of their products. This is essential in today’s highly competitive markets,” explains Timo Nittka, Automation Project Manager at ZwickRoell.

Reduce risk through incorrect operation

The automated testing machine for sheet metal forming testing reliably selects the punching tools itself by identifying the samples using a 2D code. This automatic specimen identification ensures that each specimen is precisely recognized and assigned and also guarantees safe and reliable test results.

Another advantage: the workload of employees is significantly reduced: Operators only have to fill the magazine with samples – the system takes care of all other steps automatically. Automation therefore significantly reduces the manual workload and also minimizes the risk of operator errors. The integrated camera system, which determines the test results independently of the operator, also contributes to this. Subjective decisions by the operator, such as the detection of cracks, are completely eliminated. This leads to greater objectivity and reproducibility of the results.

© ZwickRoell GmbH & Co. KG

Test up to 100 samples – without interruption

Particularly noteworthy is the ability to carry out tests in a “ghost shift”. The magazine can be filled with up to 100 samples so that the machine can work throughout the night without interruption and independently of the operator. This promotes the utilization of the machine and at the same time increases the efficiency of the testing processes. For special requirements, manual operation of the punch and the sheet metal forming testing machine is also possible in order to test special samples flexibly. Another highlight is the consistent operating philosophy: customers who already use automated tensile testing systems from ZwickRoell benefit from standardized software. Operation and data import and export are identical for the new sheet metal forming testing machine, which considerably simplifies training and use of the machines.

“The automated sheet metal forming testing machine (BUP) has the potential to fundamentally change the way sheet metal forming tests are carried out. It has been developed to meet the growing demands of the industry while offering maximum precision and efficiency,” says Nittka.

Background

ZwickRoell is a leader in materials and component testing and customers benefit from over 160 years of experience in various industries. In the 2023 financial year, the company generated revenue of €304 million. The ZwickRoell Group has production sites in Germany, Austria, Great Britain and China as well as branches and agencies in 56 other countries. ZwickRoell currently has more than 1,800 employees, 1,200 of whom work at the Ulm site.

Web:

www.zwickroell.com