The Harting Technology Group, headquartered in Espelkamp, is one of the largest manufacturers of connectors in the world. Among other things, the company develops products for the solar and wind energy, electromobility and hydrogen production and robotics sectors, thereby making an important contribution to a sustainable energy future.

An important partner on this journey is Rösler Oberflächentechnik, which has been supporting Harting with reliable machines and service for over 30 years. This long-standing cooperation with the surface specialist was also the reason for the decision to use a proven system concept from Rösler in the new Harting plant in Hai Duong, Vietnam.

Harting opened a production facility there in mid-2023, where both small plastic connectors and heavy-duty aluminum connectors are manufactured. Production is carried out according to the motto “In the region for the region” for the Asia-Pacific region. Harting invested in a new Rösler mass finishing system to ensure that the new plant can also process the so-called heavy connectors efficiently and to the usual high quality standards. This technology is already being used successfully at other locations, including in Germany and China.

Philipp Borcherding, Plant Manager of Harting Vietnam, emphasizes: “The very good business relationship with Rösler and the trust in their machines convinced us to make this investment.”

© Rösler

Different aluminum connectors for a variety of industries

Connectors are essential for the efficient functioning of electronic systems in almost all sectors, including the automotive, telecommunications and green energy industries. The Vietnam plant is intended to meet the high demand in the growth market of South East Asia and ensure local supply to customers. The heavy-duty connectors that are processed in the Rösler assembly plant are mainly supplied to the markets in Japan and Korea, especially the robotics industry, so that Rösler is also involved in this fast-growing future market with its technologies.

Harting has specialized in the production of aluminium connectors at this site. The housings are first produced using the die-casting process and then mechanically processed, whereby threads are milled and holes are drilled. The coolants and lubricants used in this process make subsequent parts cleaning necessary, which is carried out in the Rösler linking facility in parallel with the machining of the surfaces and the deburring of the edges. This process step prepares the workpieces for a subsequent powder coating process, which is used for corrosion and surface protection. The size of the machined connector housings varies from 60 x 40 x 30 millimetres to 220 x 140 x 60 millimetres, and 1,500 parts can be machined per batch, depending on the size of the workpiece.

Proven multi-stage production process for the best results

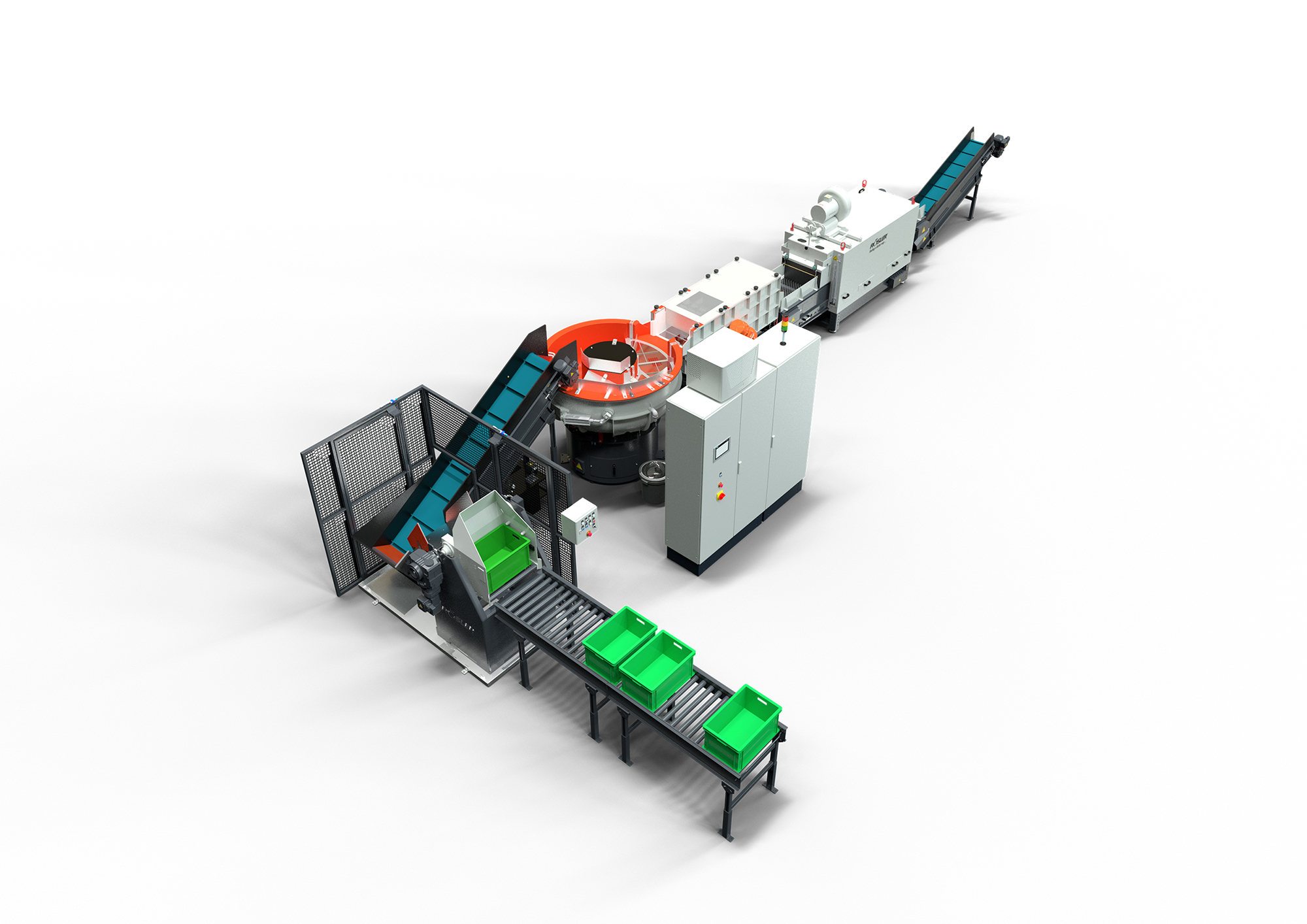

The Rösler interlinking system consists of six units: The workpiece boxes are transported to the loading unit via a roller conveyor using a tilting device and fed onto the infeed belt. There, the system operator selects the appropriate processing program depending on the size and geometry of the component. The connector housings are then automatically fed from the feed belt into a circular vibrator, where they are deburred and degreased in a single process step. At the end of the defined processing time, the machine begins to automatically empty the circular vibrator and the parts are separated from the grinding medium via a mesh screen. They are then sprayed with a water/compound mixture on a vibration washing system and cleaned with a separate process water supply before being dried in an automatic continuous drying system. The parts are then transported via a conveyor belt to the customer’s transport containers. With a few exceptions, such as the selection of the processing program, the process runs completely without the support of the operating personnel.

In order to keep noise emissions as low as possible for the workers, the entire system was enclosed in a soundproof cabin that is almost 13 meters long and 3.7 meters wide. An intelligent process water cleaning system rounds off the unit: A semi-automatic Z800 basket centrifuge for separating the solids from the process water is also integrated into the system linkage. Post-treatment of the treated process liquid takes place in a vacuum evaporator. Both occupational safety and ecological aspects are usually not an issue for competitors or comparable production facilities in South East Asia, so that Rösler and Harting are jointly setting completely new impulses in the region.

As the machining process was transferred from the five identical Rösler interlinking systems that Harting already has in operation, no re-evaluation was necessary. Only a few minor adjustments were made and the transitions between the individual elements of the linkage were adapted. “We developed this process together with Harting and have continued to optimize it so that it can be optimally integrated into the company’s production conditions and delivers the best processing results that meet our customer’s high standards,” says Matthias Ender, Technical Sales Manager at Rösler.

Strong partnership with a future option

The mass finishing line was commissioned at the end of 2024 and currently processes around 300,000 to 400,000 aluminum connectors per year “We are more than satisfied with the system. The entire handling concept, the high degree of automation that Rösler offers and the durable and robust design of the system continue to impress us. The same goes for the many features in terms of work safety and, of course, the quality of the parts, which is much better than the usual standard in Asia,” explains Philipp Borcherding. “The technical sophistication of the Rösler linking system is also excellent and works reliably.”

With this system, Harting is also relying on European know-how and the proven partnership with Rösler in the Southeast Asian market. “We have had nothing but good experiences with Rösler over the decades and know that we can rely 100 percent not only on the systems but also on Rösler’s worldwide service,” Borcherding continues. “In view of the enormous dynamism with which the Southeast Asian region is currently growing, we at Harting are very interested in the consistent and continuous further development of the Vietnam site. We will of course involve Rösler in this development as a strategic partner.”

Web:

Hall 10, Stand 10608