At Battery Show 2023, Laserline presented energy-efficient solutions for industrial material processing in the field of electromobility. The main topics were copper welding with blue 3 kW CW diode lasers, brake disc cladding to reduce urban particulate pollution, laser drying processes for the economical series production of lithium-ion batteries, and welding applications for sealing battery boxes.

One of the highlights of the trade show presentation was the world’s first blue diode laser with 3 kW CW output power (CW = continuous wave), which was developed in particular for processing copper components – for example in electrical drive technology or power electronics. It represents the current highest performance class of industrial lasers in the blue wavelength spectrum around 445 nm, which is absorbed much better by non-ferrous metals than infrared radiation.

Among other things, blue lasers enable near-surface heat conduction welding of thin copper components and offer two decisive advantages over competing approaches using green laser light: First, direct light generation using laser diodes eliminates the need for complex and efficiency-reducing frequency conversion. On the other hand, the laser systems are significantly more space-saving, which enables uncomplicated system integration. Up to CW output powers of 2 kW, the blue lasers are even available in a compact 19″ design, making them particularly easy to integrate.

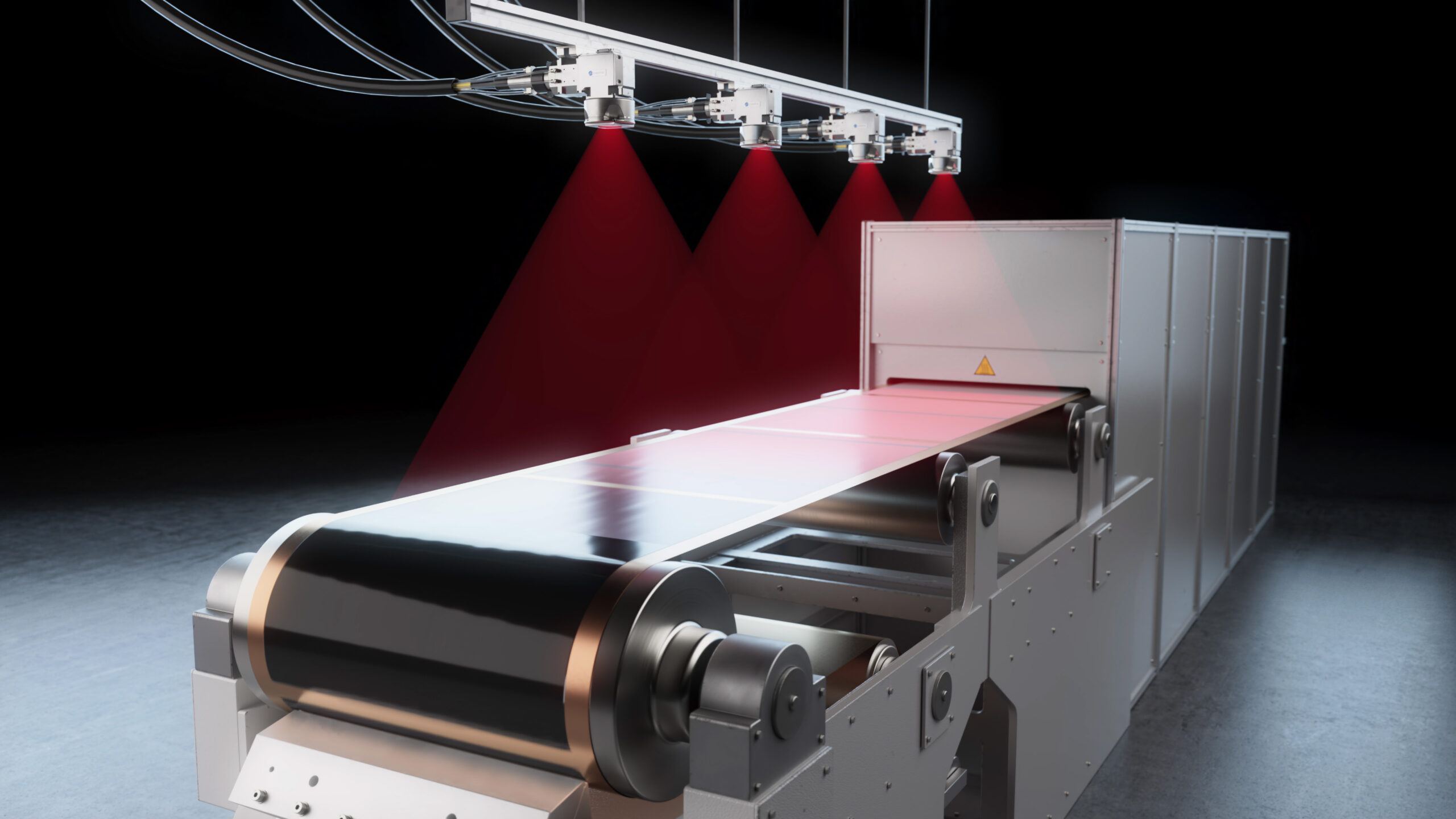

Another focus of the trade show presentation was a laser drying process for low-emission and economical series production of lithium-ion batteries. It was developed as part of the IDEEL research project (Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production) under the leadership of Laserline and enables the production of laser-dried anodes and cathodes in a roll-to-roll process for the first time.

The diode laser supplements or replaces the market-dominating convective drying process and reduces the total energy requirement for drying by more than 25 percent, while at the same time reducing the required production area. Considering connected loads of over 1,000 KW for a conventional GigaFab drying line, this is an energy turnaround in the production process that enables significant CO2 savings.

Laserline also presented a high-speed process suitable for series production for the cost-effective hard coating of brake discs. It enables the construction of very thin yet resistant coatings that combine long-term corrosion and abrasion protection and thus reduce the braking process-induced amount of environmentally and health-hazardous particulate matter with particle sizes of no more than 10 micrometers (PM10) by up to 90 percent. This also allows compliance with the requirements of the Euro 7 vehicle emission standard, which is due to come into force in 2025 and for the first time sets specific limits for particulate emissions from braking systems.

As another highlight, Laserline showed diode laser-based welding solutions for sealing battery boxes. Both a hot-wire application and an application using spot-in-spot module optics, in which a tightly focused internal spot is overlaid by a larger rectangular spot, were presented in this area. Compared to conventional processes such as MSG or MIG welding, both approaches are convincing thanks to higher process speeds, improved gap bridgeability and durable welds of outstanding quality.

Background

Laserline GmbH, based in Mülheim-Kärlich near Koblenz, was founded in 1997. As a leading international

manufacturer of diode lasers for industrial material processing, the company has now become the epitome of this innovative technology and can look back on more than 25 years of history. Nearly 6,000 high-power diode lasers from Laserline are currently in use worldwide, demonstrating their performance in a wide variety of processes and applications. Laserline currently employs around 350 people and has international offices in the USA, Mexico, Brazil, Japan, China, South Korea and India, as well as representatives in Europe (France, Great Britain, Italy) and in the Asia-Pacific region (Australia, Taiwan). The company is focused on sustainable growth. The construction of an extensive building complex on the site in Mülheim-Kärlich has already created the spatial prerequisites for the future expansion of development and production.