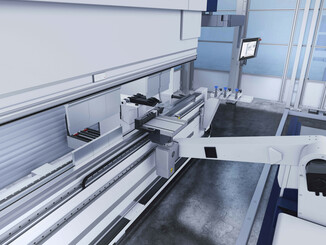

The TruBend Cell 5000 Lean Edition from Trumpf can process automatically for eight hours.

At Blechexpo, Trumpf will be presenting the TruBend Cell 5000 Lean Edition, a new automated bending cell for the mid-price segment. Depending on the component geometry, the machine can work for around eight hours without supervision. This counteracts the shortage of skilled workers. “Automation is one of the most important future trends in bending. With the TruBend Cell 5000 Lean Edition, we are offering users with a limited investment budget a solution for getting into automated bending and making their production competitive. This means that Trumpf can make every customer a suitable offer,” promises Simon Hiebl, Head of Product Management Premium and Systems Bending at Trumpf. With the new TruBend Cell 5000 Lean Edition, the Trumpf developers have relied on proven hardware and software. For example, they use the BendMaster bending robot and the TruTops Boost software for programming. This makes the bending cell particularly reliable and productive. This counteracts the shortage of skilled workers.

© Trumpf

Suitable for a wide range of parts

The high-tech company offers the TruBend Cell 5000 Lean Edition in two versions – with and without a small parts package. In the basic version, companies can process parts in A4 to Euro pallet format. With the small parts package, even small components, just the size of a business card, can be bent. “With this wide range of parts, users can process a large proportion of their orders automatically with just one machine,” says Hiebl. Small to medium-sized components, such as e-charging stations, control cabinets and PC housings, can be produced very well with this.

Employees can also program the machine very easily. This is made possible by the intuitive user interface of the TruTops Boost software. This shortens the training period and employees can start working on the machine more quickly. Users can also place two different grippers inside the bending cell. This enables the machine to be changed over to another component quickly, flexibly and automatically. Trumpf is launching the solution in both equipment variants at Blechexpo.

Web:

www.trumpf.com