The SAP solution Production Engineering and Operations (PEO) is aimed at companies that are active in discrete manufacturing in the broadest sense. It links designers, planners, production controllers, work planners and workers on one platform with the same database.

If you take a closer look at the business processes of manufacturing companies, you will notice the multitude of heterogeneous system landscapes consisting of various PLM, QM, MES and ERP software solutions. As a result, the efficiency of production suffers significantly.

Reason: Engineering and order change processes cause high process and quality costs due to the insufficient integration and the associated complex bidirectional system interfaces – especially if you take into account an increasing product variety through Engineer To Order (ETO), Make To Order (MTO), Configure To Order (CTO) and Assemble To Order (ATO), which is typical for special machine construction and its very complex products with a comparatively long lead time.

This presents users in particular with the difficult task of establishing a solid change management system that meets their own and their customers’ requirements.

game changer

SAP’s answer to this problem is called “Production Engineering” and “Production Operations” – PEO for short. This module, which is fully integrated into S/4HANA, allows the production landscape to be homogenized, because from a technical perspective, PEO is located between product development (R&D) and aftersales service – in other words, in manufacturing.

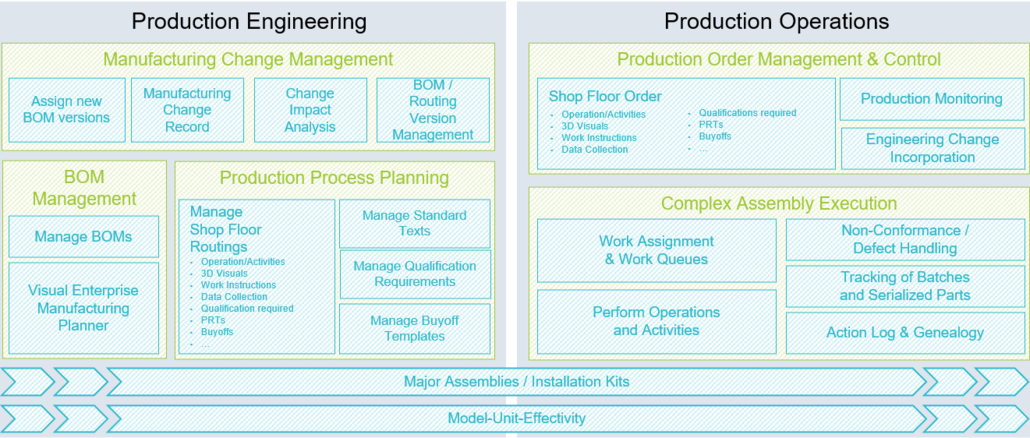

At its core, the solution consists of two large areas, PE and PO, which contain a number of sub-modules and functions.

Until now, SAP’s core system did not offer a reasonable interface for data transfer to SAP PP – which meant that users had to work with lists without 3D models. S/4HANA, on the other hand, is equipped with the new TDMI interface (Team Data Management Interface). SAP PEO thus understands all common CAD and PLM systems, such as those from Siemens, Solidworks, Windchill or Teamcenter.

In this way, engineering parts lists, for example, can be enriched with 3D models and additionally with PMI data (Product Manufacturing Information) such as tolerance specifications or welding points and transferred to the SAP core system. This enables very granularly resolved complex workflows that are linked to 3D parts lists. An integrated QM module also provides an inspection during production.

Under the microscope

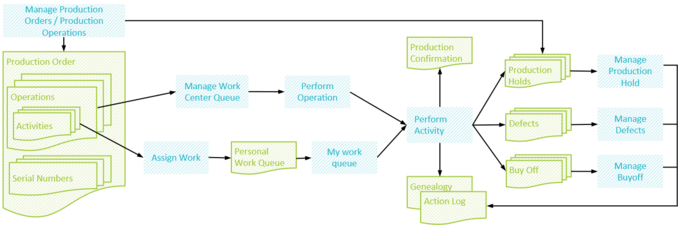

But what does PEO look like in practice? A standard process starts with the transfer of a modified or new bill of material for a product from the PLM system. The module can work with engineering BOMs (EBOM) as well as with all types of manufacturing BOMs (MBOM). These are assigned to a change record in the PEO, on the basis of which an “impact analysis” can be carried out.

The “Impact-Analysis” app in particular thus closes a gap that has been identified in many SAP projects to date. It thus supports production in quickly and efficiently determining all production objects that are potentially affected by a change – such as routings, bills of material, production orders, or purchase orders. From the “Change Record” app, changes to MBOMs – such as routings or production orders – can be planned and executed directly. This makes it the central tool for analyzing, planning and executing changes.

With the “Visual Enterprise Manufacturing Planner” (VEMP), PEO also offers a new tool for MBOM management that enables the transfer of the design structure to the manufacturing structure with the help of an interactive 3D model.

Another highlight of PEO is the use of process activities – a feature that is otherwise mainly known from MES software solutions. In this way, the production planners represent individual production operations of a routing in multiple activities in order to significantly increase the level of detail. At the same time, they have full functionality, for example, compared to the familiar sub-processes from the ERP. All aspects of a workflow, such as component assignment, work instructions, inspection characteristics, production resources/tools, documents, acceptances, qualifications, and task managers can thus be assigned to operation activities.

To ensure that the efficiency of routing maintenance does not suffer due to the large number of new options, SAP has introduced the “Drag&Drop” methodology and thus greatly improved “usability”.

PEO supplements PP

The integration of PEO in S/4HANA does not mean that it replaces classic SAP PP, but rather that it must be thought of as a supplement. All PP functionalities such as BOM and routing explosion or order creation and release are still available and act completely homogeneously with the new applications and functions.

The activities are mainly used for planning, scheduling and costing, whereas the newly introduced activities are used in shop floor execution. A special feature is also the production of serialized assemblies. Here, Order Management and Order Control as modules of the TOE offer extended track-and-trace functionalities in the context of serialization.

The well-known work lists, which are often created in SAP with the help of Excel or Z-Tools, can now be called up directly in SAP PEO. The new solution distinguishes between personalized work queues for workers or workstation/resource-based queues. Backlogs, defects and buy-offs can be initiated directly from the UI (Perform Operation Activity) created for the worker.

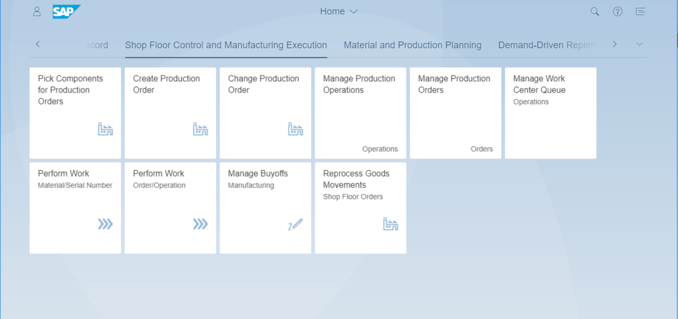

All information that accumulates during the execution of activities, as well as all backlogs, defects and buyoffs are documented in the action log – at the granularity of the serial number. This increases process reliability and avoids expensive rework. In addition to classic GUI transcations, the system offers a variety of user-friendly applications in the SAP Fiori launchpad for the entire range of functions.

On this basis, it is possible to implement and establish end-2-end processes with complete traceability with regard to engineering changes. This provides designers, planners, production controllers, work planners and workers with a platform that accesses the same database.

Author: Dominik Karosser, Consilio GmbH

Web:

www.consilio-gmbh.de