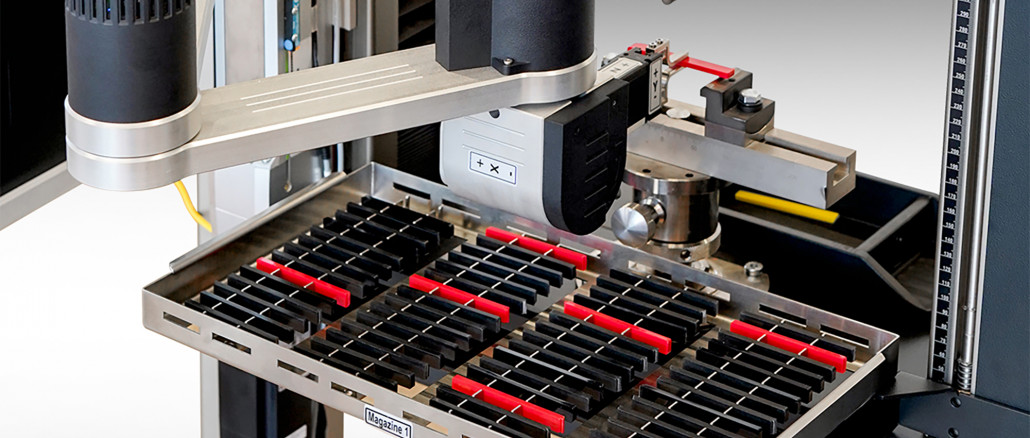

The compact automation solution ALEX (Automated Lab EXpert) for small test series is now even more versatile – with new extension packages for metal round specimens, elastomer specimens and as a retrofit solution for existing testing machines. Alex automates tensile and flexure tests from ten specimens per day, bringing efficiency and precision even to smaller laboratories. The system requires hardly any space, is immediately available and can be flexibly integrated – without the need for floor fixings.

Thanks to its space-saving design, Alex is suitable for laboratories with low sample volumes. The small robot does not need to be fixed to the floor and can be flexibly integrated into existing laboratory environments. “With Alex, we are revolutionizing laboratory automation by enabling maximum efficiency with minimum space requirements,” explains Jakob Brodbeck, Business Development & Product Manager Automation at ZwickRoell.

New expansion packages for even more application options

Following the successful launch at the beginning of 2025 with the basic automation for flat metal specimens and tensile and bending specimens made of plastic, further application packages are now following:

© ZwickRoell

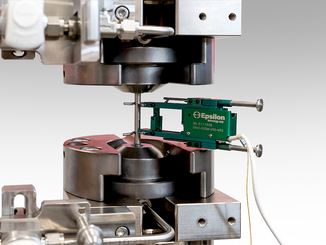

Alex for metal round samples

The compact solution now also supports round specimens with shoulder diameters of 6 to 12 mm and a weight of up to 400 g. Compatible with DIN 50125, ISO 6892-1 and ASTM E8 standards. The magazine holds 17 samples.

Alex for elastomer samples

For sticky and dimensionally unstable elastomer samples in accordance with ISO 37 (types S1 and S2), Alex offers special gripper fingers, modified scrapers and an optional thickness gauge for automatic thickness measurement at up to three points.

Alex as a retrofit solution

Existing ZwickRoell testing machines can be easily retrofitted with the robotic arm. The automation components are attached directly and securely to the aluminum profile without any complex conversions. The robot’s control electronics fit compactly underneath the testControl machine electronics.

What’s new is that Alex is now also available for older machine series – including those from other manufacturers. This means that automated materials testing is now also possible as standard for these existing systems.

Core benefits: Precision, efficiency and flexibility

With Alex, laboratories benefit from reproducible results and a significant reduction in operator influence. Manual testing remains possible at all times – thanks to the robot arm’s parking function, access to the testing machine remains unrestricted. “Our testing assistant Alex is the perfect solution for laboratories looking for automation without compromising on flexibility and precision,” says Brodbeck.

Web:

www.zwickroell.com