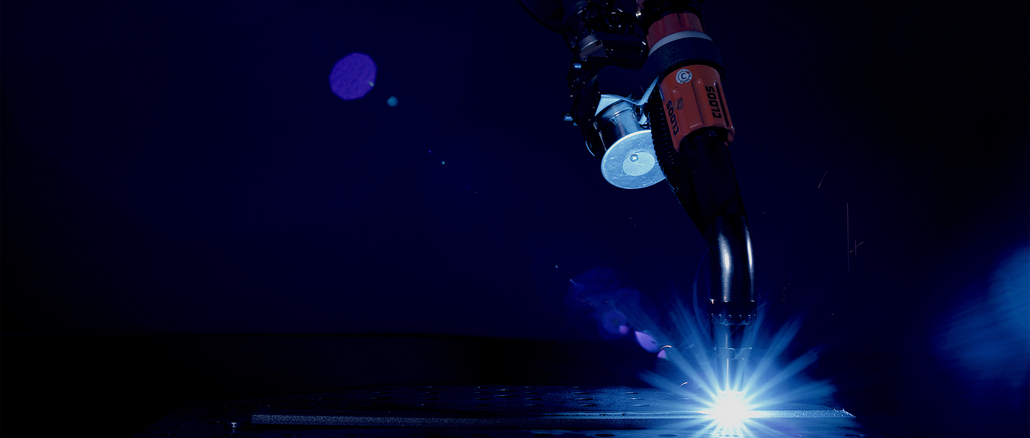

The requirements for occupational safety measures and safety technology are also continuously increasing in welding technology. The Technical Rules for Hazardous Substances (TRGS) require welding fumes and pollutants to be extracted at the point of origin in order to comply with the occupational exposure limits (OEL) for hazardous substances. The Cloos extraction welding torch system provides safe and effective extraction of welding fumes directly at the source. Up to 95 percent of the smoke is eliminated directly during the welding process at the point of origin near the arc. Employees benefit from cleaner air and a better working environment.

The measures required for collecting, extracting and filtering the flue gases in robotic systems often involve great expense. Large collection hoods with curtains, elaborate piping systems and a large filtering device are necessary to extract and clean the polluted air.

© Cloos

Reduced investment volume with low operating costs

When exhausting directly at the welding torch, the volume of polluted air is much smaller. By using the suction welding torch system, users have to invest significantly less in extraction technology, air guidance system and filter unit – with the same effect. A flexible hose with a small diameter replaces the complex pipe system for discharging the contaminated air to the filter unit. Due to the smaller volume of polluted air, a smaller filter device is necessary. Another advantage is that the optimized energy efficiency and the minimized effort for cleaning and replacement of the filter components significantly reduce operating costs.

Effortless retrofit

The available geometries of the suction welding torches correspond to the geometries of the standard welding torches in use. No complex correction of the robot welding programs is necessary. This means that existing robot systems can be retrofitted with the suction welding torch system without any great effort.

Robot and welding technology from a single source

Since 1919 Carl Cloos Schweißtechnik GmbH has been one of the leading companies in welding technology. With more than 900 employees worldwide, the company implements manufacturing solutions in welding and robotics for industries such as construction machinery, rail vehicles, energy, automotive and agriculture. The modern Cloos welding power sources Qineo are available for a wide range of welding processes. With the Qirox robots, positioners and fixtures, Cloos develops and manufactures customer-specific automated welding systems. Cloos’ particular strength lies in its broad-based expertise. Because – starting with welding technology, robot mechanics and control, up to positioners, software and sensor technology – at Cloos everything comes from one source.

Web:

www.cloos.de