A consortium led by the German Research Center for Artificial Intelligence (DFKI) has developed an underwater welding robot so that maritime infrastructure no longer has to be repaired only by industrial divers. With the help of artificial intelligence (AI), sensor technology and an underwater robotic arm, the system should enable autonomous welding work in the future.

Until now, underwater welding has been carried out by hand when repairing port facilities, offshore structures or other metal structures. However, the demand clearly exceeds the available skilled workers. This is where the Mariow (Maritime AI-Guided & Remote Operated Welding) project, funded by the German Federal Ministry for Economic Affairs and Energy, comes in: For the first time, the partners have developed a robotic system that can carry out underwater welding work largely autonomously. In future, it is intended to relieve divers and produce more precise, more even weld seams even under difficult visibility conditions.

In addition to the DFKI Robotics Innovation Center in Bremen, the project consortium included the Institute of Materials and Process Engineering and the Laboratory for Autonomous Systems at TH Köln, the Fraunhofer Institute for Computer Graphics Research IGD, AMT GmbH and Unterwasserkrause – Mutzeck GmbH, according to DFKI.

© DFKI

Modular underwater manipulator and AI support

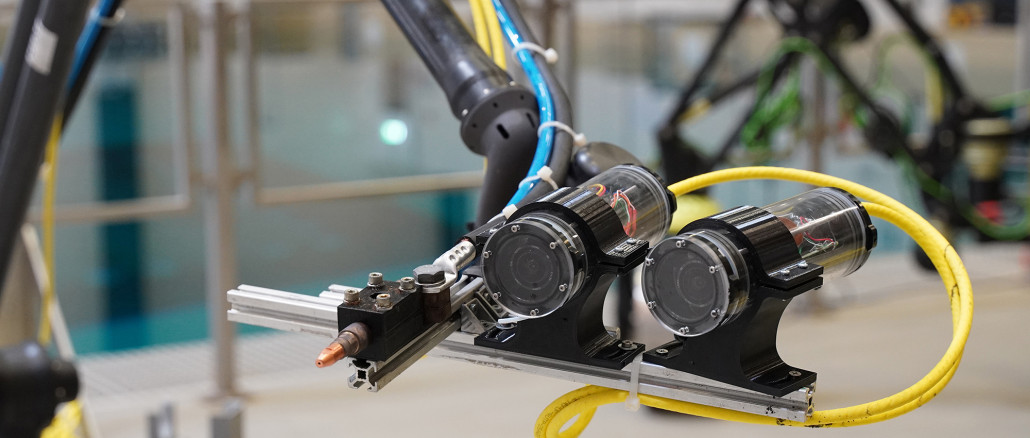

A central element is the underwater manipulator developed at DFKI. The robotic arm can be used at depths of up to 6,000 m, has a range of 2 m and can be adapted to the application scenarios. Using decentralized joint control and higher-level motion planning, the manipulator carries out the welding work precisely and with repeat accuracy.

Another core element of the Mariow system is the AI-supported determination of the welding path. The stereo camera system developed by Fraunhofer IGD provides high-resolution underwater images of the welding torch. Based on this, the Laboratory for Autonomous Systems at TH Köln has developed and trained AI models that autonomously recognize welding joints and their start and end points. The AI then calculates the optimal movement of the robot.

Innovative cored wire welding process

A decisive advance is the flux-cored arc welding process, which makes underwater welding reliably automatable for the first time. The underwater flux-cored arc welding (UW-FCAW) process developed by the Institute of Materials and Process Engineering at TH Köln together with AMT GmbH replaces conventional stick electrodes, which have to be replaced after just a few centimetres of weld seam, with a continuous wire. This uninterrupted material flow forms the basis for stable, controlled and reproducible seams.

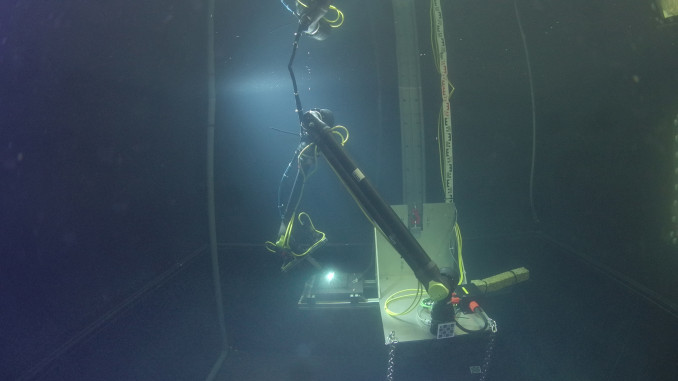

In the final project phase, all sub-applications were brought together and demonstrated in the underwater test basin at DFKI in Bremen. The complete AI-based determination of the welding line, the automated planning of the welding path and the final welding using the UW-FCAW process were implemented.

The consortium would like to expand on these results in future projects. In addition to improving the quality of the weld seam, the main focus will be on practical use in the harbor basin. The influence of salt water, currents and waves will then make it necessary to adapt the systems. In addition, the higher pressure at depth increases the demands on components, for example in terms of tightness. Last but not least, a laser system is to be integrated to remove the slag produced during welding.

Web:

www.dfki.de