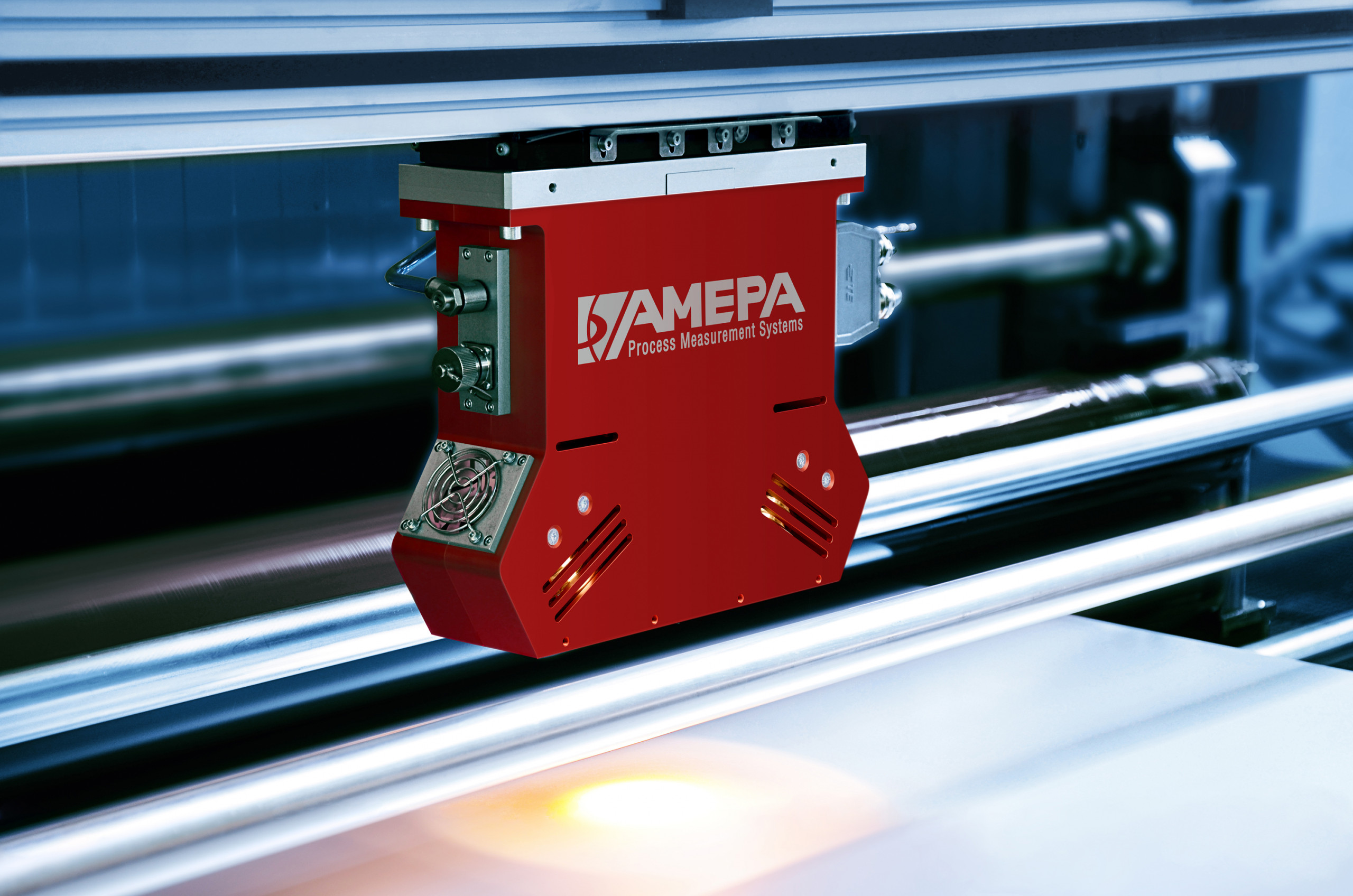

Limax will be presenting the new modular electrostatic oiling machine for aluminum strip for the first time at Aluminium 2024. It combines the proven secondary tension for ultra-fine atomization with flexible width adjustment, a new, integrated smoothing roller and inline measurement of the oil layer from Amepa.

With this combination of components, it produces an evenly distributed oil layer, significantly reduces oil consumption and warns of dry streaks or over-oiling in good time.

© Limax

It combines the advantages of electrostatic oil application with precise measurement of the oil layer in a single unit.

Limax will soon be delivering the first example of the new generation to a customer in North America.

In the new machine, Limax continues to work with additional secondary electrodes above the belt.

They generate oil droplets with a diameter in the hundredths of a millimeter range, while at the same time spreading the spray mist.

Compared to systems without secondary electrodes, the spray is much finer and more homogeneously distributed on the belt.

A special feature is the flexible adjustment of the spray width.

It can be adjusted to the width of the respective belt in steps of 100 mm.

In this way, Limax avoids overspray on narrow belts: Only the amount of oil that is actually needed is sprayed.

They significantly increase process reliability, as the combination of the measured values of the electrostatic oiling with those of the infrared spectrometry sensors makes it possible to warn of “dry streaks” on the belt or localized over-oiling in good time.

Another trade fair innovation is the homogenizing roller developed by Limax, which generates a constant pressure across the entire width of the belt and thus a uniform thickness of the oil layer.

Cedric Maresch, Managing Director of Limax GmbH, sees great advantages for his customers in the cooperation with Amepa and Danieli: “With the new system, we reduce the amount of oil and still achieve a homogeneous distribution. An important step is the integration of Amepa’s inline measurement into our machine. The data exchange between the two measuring systems ensures that anomalies in the oil application are detected quickly and operators can take immediate action. This means that only perfectly oiled strip enters the press line.”

Web: www.limaxgmbh.de