Kasto will be presenting automatic band saws and intralogistics solutions for the metal industry at AMB (September 10 to 14 in Stuttgart) at stands 8B24 and 8B21 in hall 8.

This enables users to process material efficiently, precisely and sustainably and to digitize and automate their processes.

© Kasto

It processes solid material, tubes and profiles made of stainless structural and tool steels up to 360 millimetres wide and high.

The pre-tensioned linear guides guarantee maximum service life and precise length positioning thanks to the ball screw drive of the material feed.

Another highlight is the frequency-controlled spur gear saw drive with overload and clamping pressure monitoring.

This enables users to achieve a high cutting performance and precise work processes for single cuts, small and medium batch sizes and large series.

The infinitely adjustable, electromechanical feed with servo motor and ball screw spindle guarantees efficient, tool-friendly sawing.

With the Kastotec AC 4, the specialist is presenting a fully hydraulic high-performance band saw with a heavy-duty design.

It is particularly suitable for cutting round, square and flat material as well as pipes and profiles in all qualities up to 430 millimetres wide and high.

Specially designed for difficult-to-cut materials such as titanium, Hastelloy and Inconel, the machine has hydraulically pre-tensioned carbide slideways and electronic monitoring of the hydraulic saw blade tension.

The cutting speed is infinitely variable and the horizontal clamping vices are equipped with a free-lift device as standard.

The standard equipment also includes the proven KPC package (Kasto Performance Cutting), which comprises all essential functions for optimum sawing performance and durability.

© Kasto

More storage space in a smaller area

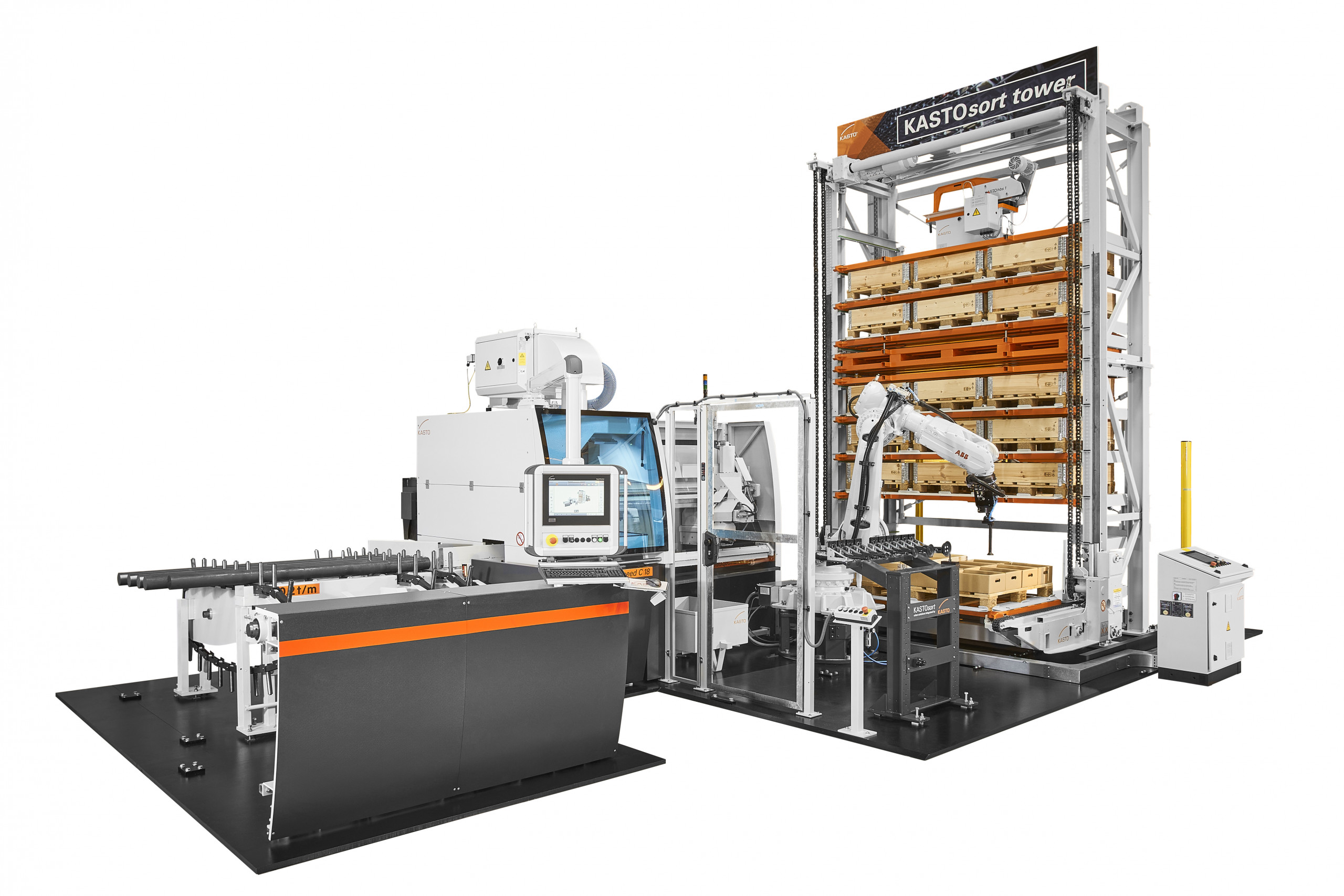

The Kastosort tower enables space-saving parallel sawing, sorting and storage.

It automates material flows even where space is very limited and is perfect for unmanned processing – especially for metalworking companies that already use high-performance saws such as Kastovariospeed or Kastotec.

After sawing, the integrated Kastosort tower sorting solution provides significantly more storage space in a smaller area.

The developers combined reliable technologies to create a highly productive system consisting of a chain magazine, the Kastovariospeed circular saw, the Kastosort robot and the Kastoecostore storage system.

This only requires a little more than eleven square meters in medium format and still offers a storage height of up to eight meters.

© Kasto

Smart solutions from app to temporary storage

In addition to high-performance systems, Kasto also focuses on comprehensive digital solutions for sawing, storage and service.

In the SmartSolutions Corner at AMB, for example, the company is presenting the platform-independent web application Kastoapp.

It enables users to monitor the live status of their sawing machines at any time and from anywhere via mobile device or computer and to react quickly.

Kastooptisaw supports processing with powerful algorithms to optimize cutting arrangements.

This tool can be integrated as an add-on to the Kastologic Warehouse Management System (WMS).

The graphical, user-friendly interface of the WMS enables users to carry out efficient work processes in their daily warehouse work, from simple control to order processing.

Metal processors can reduce their energy consumption with Kastoenergysave.

The sustainable solution converts excess kinetic energy into electricity and stores it for later use.

This reduces operating and investment costs in the long term and has a positive impact on the CO2 footprint.

Kasto will also be providing information on many other solutions and systems that make users’ processes more efficient and are individually adapted to their needs.

These include, for example, the Kastopick bar robot solution, which enables steel companies to pick and deliver flat, square and round material as well as round and profiled tubes fully automatically without the need for personnel.

Visitors to the trade fair will also learn more about the new Unitower CNC, which provides space-saving intermediate storage for workpiece carriers for CNC machining centers.

Operators can use it to supply their production fully automatically, even during the night.

Web: www.kasto.com