Experience shows that pilot customers of new technology have to be prepared for tests of patience: Beuting Metalltechnik GmbH & Co. KG, metal processor and manufacturer of cutting tables, nevertheless dared the “stress test” with three new products from Messer Cutting Systems: the Element 400 L laser cutting machine, the Global Connect control system and the new Laser Nozzle Control (LNC) nozzle changer. The long-standing partnership between the companies was the ideal basis for this tough test for man and material.

The entire industry of steel service centers, contract cutters and metal fabricators is under pressure. Thus, Beuting Metalltechnik GmbH & Co. KG from Vreden also has to meet the increased demands of its customers on the quality of the parts in order to remain competitive. The shortage of skilled workers is another complicating factor: “In the future, all the parts we supply to our customer will be processed on robot welding systems. We have to prepare for this by automating and digitizing our production processes,” explains Mechthild Beuting, Managing Director of the company. “Our experience has been that plasma cutting systems are more difficult to automate and machine operators are harder to recruit for plasma cutting systems than for laser cutting systems. In addition, employees are becoming less willing to work shift systems.”

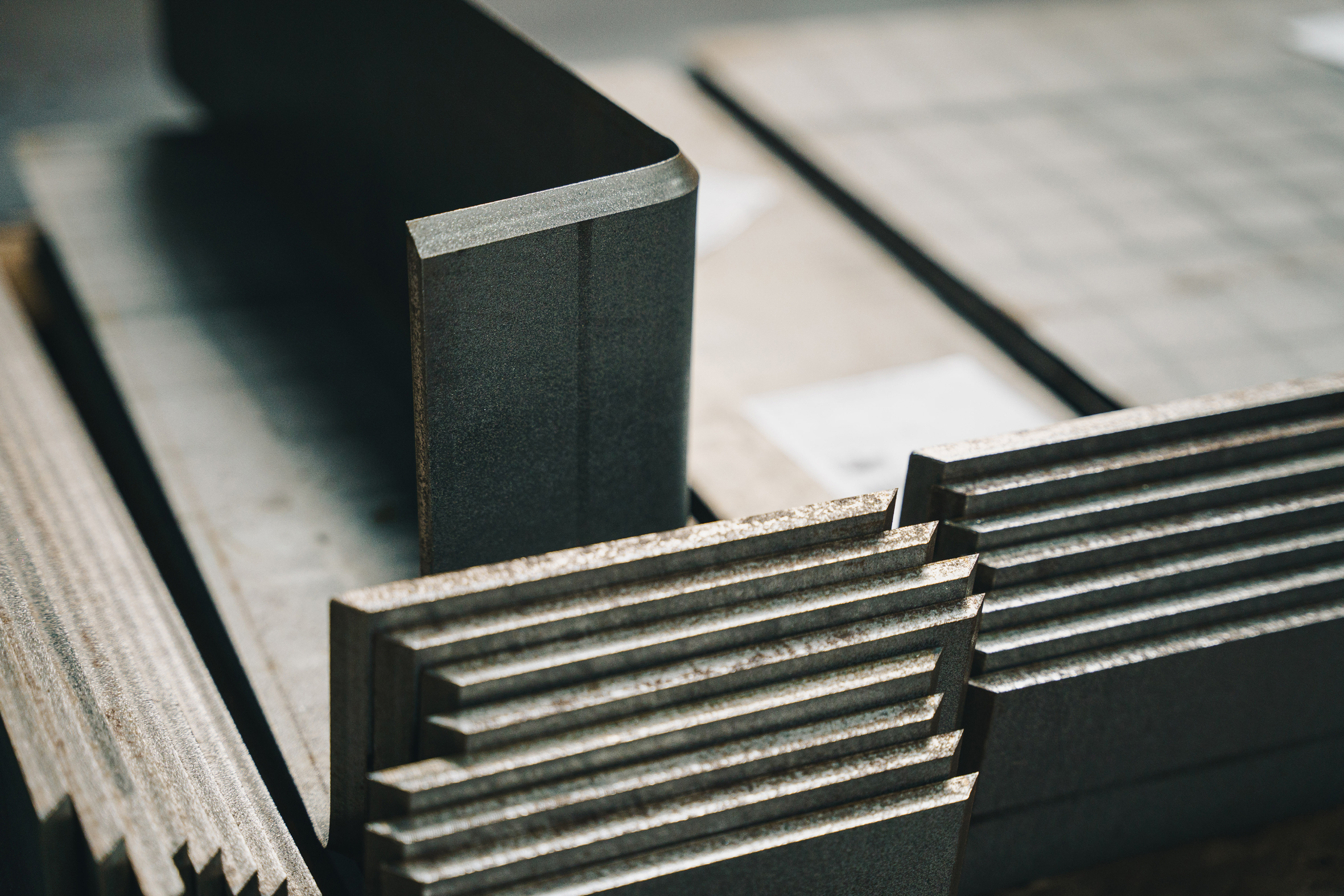

© Messer Cutting Systems

Increased requirements

The plasma cutting system from Messer Cutting Systems from 2006 could no longer meet these increased demands and Beuting had to find a sustainable replacement solution. However, the requirements were very high.

The new cutting machine not only had to be state-of-the-art, but also capable of cutting sheet formats up to 3 x 8 m with a sheet thickness of up to 20 mm as well as burr-free cuts. Chamfers should be possible up to 15 mm, with 90 percent chamfered parts with a maximum angle of ±50° and a tolerance of less than 0.5 mm with V, Y, X and K seams. It was also important to Beuting that the new machine could process sheets with varying surface quality – blasted, lightly rusted, primed, oiled, etcetera.

“The main focus for us was in particular the intuitive operation of the machine. Our operators should be able to handle the machine alone and safely after a short training period and operate it in a second shift with only one operator. In addition, it had to be possible to integrate our own shuttle table system into the machine,” says Stefan Tenhumberg, project manager at Beuting, explaining the technical requirements. “We also need a lot of flexibility to be able to upgrade the machine to higher laser powers as customer requirements increase and more powerful laser sources become available.”

Ulrike Beuting, project manager for digitization and prospective managing director, is thinking one step further: “Of course, we also want to push ahead with the automation of our production. The first step is to transfer orders from the ERP system to the machine and have the machines report back evaluable real-time data on times and quantities. For this, we needed a sensible and functioning overall concept.”

© Messer Cutting Systems

New territory for all involved

After extensive market analysis, Beuting decided on the Element 400 L laser cutting machine from Messer Cutting Systems with a new Bevel-U bevel head and 8 kW IPG laser source as well as an automatic nozzle changer (LNC) and the Global Connect machine control system. Further digitization of production is achieved with the latest version of the CAD-CAM nesting software OmniWin and the digitization suite OmniFab with the modules ERP-Connect, Job Management, PDC and Machine Insight.

“When we decided on this solution, we were very aware that not only we were entering absolutely new territory with the Element L, the LNC and the Global Connect, but also Messer Cutting Systems,” recalls Mechthild Beuting of the decision in 2021.

Ingo Staudinger, Product Manager Material Handling and Laser at Messer Cutting Systems, adds: “It was also clear to us that the introduction of three new products at one customer meant a maximum challenge for both sides. But the partnership relationship that had already existed since 2006 was so good that we were able to take the step together.”

First, the old plasma cutting machine had to be dismantled and the foundation for the new machine created. This was followed by the assembly of the special raceway by Messer Cutting Systems and the installation of the shuttle table system from Beuting. Regular production operation of the Element 400 L with one shift has been running since December 2021.

The stress test on a strong basis

“The Element L for Beuting was our prototype for new laser cutting machines beyond the 6-kW limit that has existed for years. The highest priority was to secure the combination of new machine, new Global Connect control system and LNC as a prerequisite for automation. The close cooperation with our partner Beuting helped us to jointly bring the project to market maturity under production conditions,” says Ingo Staudinger.

Alfred Beuting, Managing Director of the company, sums up: “All those involved, including the management of Messer Cutting Systems, have always played their part in solving the upcoming tasks, some of which were very difficult. The open communication and the fact that we have known and appreciated each other for many years helped us a lot here. The project was a stress test for our long-standing business relationship. We are still not quite finished, but both sides are optimistic that this will be the case shortly.”

The business relationship between the two companies began in 2006. At that time, Messer Cutting Systems qualified Beuting as a supplier of environmental technology. Over the course of time, this cooperation has resulted in an extensive range of products, some of which were developed jointly, such as oscillating conveyor tables, belt conveyor tables, filter systems, water conveyor tables, shuttle table systems and much more. Over the years, the business relationship developed into a partnership of equals.

© Messer Cutting Systems

Close development partnership for project success

The integration of the Element 400 L with LNC and Global Connect into Beuting’s production became a joint development project. Beuting only agreed to purchase the prototype because of the close long-standing relationship. Beuting was thus able to contribute a great deal of its own know-how to the development via the cutting process. At the same time, the launch of the new products also took collaboration to a new level: in the newly formed development partnership, both parties were prepared to take risks in order to exploit new opportunities. It was worth it.

“Our partnership has emerged stronger from the project. It has significantly advanced both sides and improved our market positions,” Alfred Beuting sums up.

Ingo Staudinger agrees: “By combining Messer machines with Beuting’s environmental technology, we have jointly developed a competitive advantage. Both sides benefit from the close cooperation. We pay attention to each other’s interests in the dialog with our customers. Even for difficult tasks, we have always been able to find a solution.”

Open communication, mutual trust, a common focus on the benefits for the end customer and the will to innovate are the guarantees for success, all those involved agree.

Expectations exceeded

Even though not all challenges have been solved yet, the experience so far is clear. Stefan Tenhumberg: “The precision with which the machine cuts the components has clearly exceeded our expectations. One of our customers can now weld the parts all automatically and only wants components from the Element 400 L. We now cut a wide variety of structural steels and fine-grain structural steels automatically without manual intervention, even with varying surface quality. The cutting times compared to the plasma cutting process have been significantly reduced for the same assemblies. Our operators are pleased with better working conditions in terms of dirt and noise and have great fun working with the new machine and its new control system.”

Mechthild Beuting also sees the whole thing very positively from a management perspective. The competitive edge that the new machine has brought is already clear, he says. Product quality has been greatly improved and the attractiveness of the operator’s workplace has been significantly increased. “We are already using the system very successfully, even on shifts with few men!”

The advantages in digitization also speak for themselves. “Many work processes in order processing, manual material bookings as well as rework costs are eliminated and reduce time and costs. The higher cost transparency means that we can further optimize processes,” Ulrike Beuting adds to her mother.

Lisa-Marie Beuting, second daughter of the family and also successor to the management, is also pleased with the result: “Through the joint development work, we were able to significantly reduce non-productive time and increase the productivity of the machine. We were able to influence many details. Another advantage is the intuitively operated Global Connect, which now only takes a short time for the operator to learn.”

© Messer Cutting Systems

Next steps

Beuting is already planning further: automation and digitization are central topics here. For example, Element L is to be further optimized and material logistics automated. The plan is to link the machines to the ERP system so that manual recording of times and quantities is no longer necessary. Production planning and order processing are further digitalized with OmniFab. The evaluation of the machine data should bring more transparency and further improved cutting processes.

In addition, laser powers are to be increased as lasers become more superior to plasma. The management wants to counteract the increasing shortage of skilled workers with attractive jobs. Increasing technical requirements of customers, who are also automating and digitizing their processes, will be met with the help of innovative technologies.

“Despite the stress test, we would opt for this solution again at any time,” concludes Mechthild Beuting. “For future projects, we can say with a clear conscience that, in our opinion, this is the best technical laser cutting machine with the most advanced control system for cutting bevel parts available on the market at the moment. That’s why we have just ordered the second Element L and this time with 15 kW laser power.”

Productivity redefined

The Element L is a flexible solution for laser cutting applications where the highest precision is required. It scores with high dynamics and the latest laser technology. Even XXL sheets can be processed economically and with little manpower. The combination of various features and powerful software ensures maximum productivity and performance. With the unique design of the Bevel-U, precise and repeatable bevel parts can be produced. A great advantage for edge preparation and especially for automated welding.

With the Element 400 L, working widths between 1,600 mm and 5,100 mm and a working length of up to 25,000 mm are possible. It cuts mild steel sheets up to a thickness of 40 mm. With positioning speeds of up to 140 m/min and high acceleration (combination X/Y axis), it is very fast and has high positioning accuracy thanks to the linear guides in the X and Y axes. The calculated construction of the portal also contributes to this.

Up to six tools can be integrated in the Element 400 L – including automatic tool selection and positioning. The user can also combine the latest laser technology (maximum two stations) with advanced plasma cutting technology.

Today, automated processes are the basis for economical and precise manufacturing. A feature for the automation of the Element 400 L is the nozzle changer (LNC). It quickly and reliably automates setup operations for maximum machining quality and productivity – for any material, any thickness, and any process – without manual intervention. Before each job, the LNC option first checks whether all the necessary nozzles are present in the station.

In addition, the nozzle quality is regularly checked and the nozzle cleaned to ensure high process reliability. In the event of a defect or a different sheet thickness, the nozzle is automatically replaced. In addition, the centricity of the laser beam to the nozzle is checked, and the scanning is automatically calibrated. This ensures reliably high cutting quality and reduced setup times. Machine downtimes are prevented and the sheet metal worker gains planning reliability and optimization.

The Element 400 L is rounded off by the powerful software solutions from Messer Cutting Systems. They ensure maximum transparency of operational processes, production planning and control. To further pave the way for continuous networking, the Global Connect can handle production orders directly and achieve maximum productivity, especially in combination with the products of the OmniFab family. The fact that the user interface remains clear and simply structured helps the user to access and operate all features without any problems.

With maximum protection against operating errors, it gives beginners a lot of confidence after a very short time. More experienced operators can utilize the full functionality of the machine without triggering malfunctions with the help of numerous new features. The Global Connect provides quick access to a wide range of production data, minimizes unplanned downtime and operator error, and reduces paper and material handling inefficiencies and labor.