Metal Production

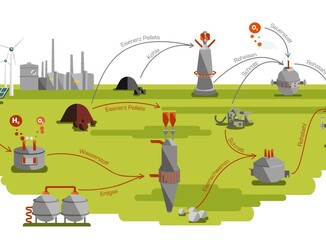

SMS supplies blast furnace decarbonization technology

SMS Group will improve the efficiency of processes at Magnitogorsk Iron & Steel Works (MMK) by using “syngas”, a combination of hydrogen and carbon monoxide, which will replace part of […]