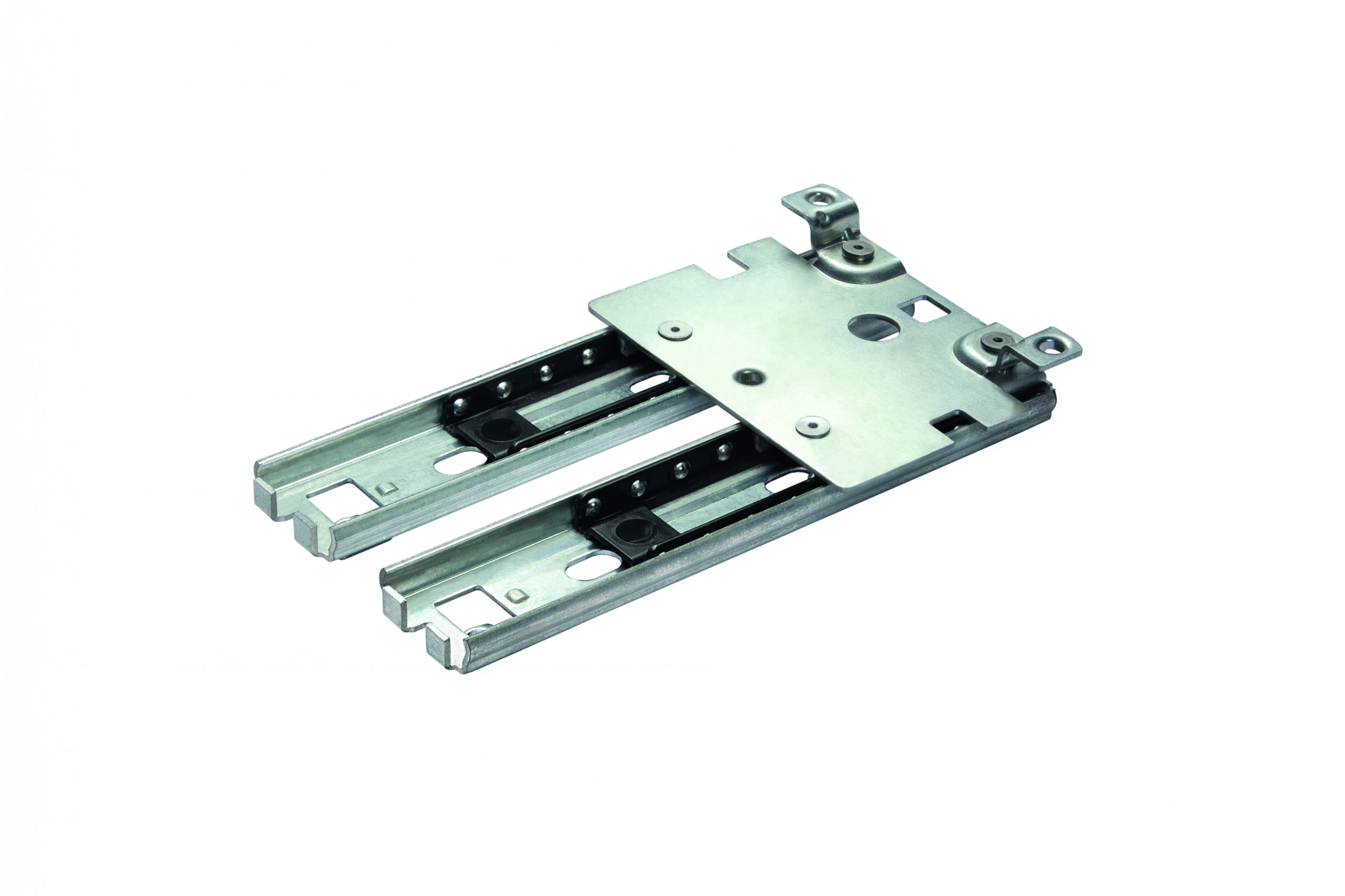

October 2021 is a special occasion for Schock Metall: 50 years ago, on October 1st, 1971, the new metal plant of Schock GmbH, then located in Schorndorf, was opened in Urbach. Under the management of Richard Schock, the company specialized in the production technologies of punching and roll forming. At that time, the production program included decorative metals for radio, television and phono equipment, but also telescopic slides and drawer runners for the furniture industry.

Today, the Schock Metall Group with its six locations in Germany, Latvia and the USA is a leading international supplier of customised telescopic slides and special profiles. Around 450 employees work for the owner-managed company in Germany and abroad.

The most important target markets include the kitchen furniture, household appliance and automotive industries. In addition, Schock Metall also supplies customers in various industrial sectors, for example in the field of warehouse and factory equipment. As a result of the Covid-19 pandemic, medical technology came increasingly into focus, as numerous hospitals procured their own laboratory equipment, which is fitted with correspondingly high-quality guidance systems and assemblies.

Core competence roll forming

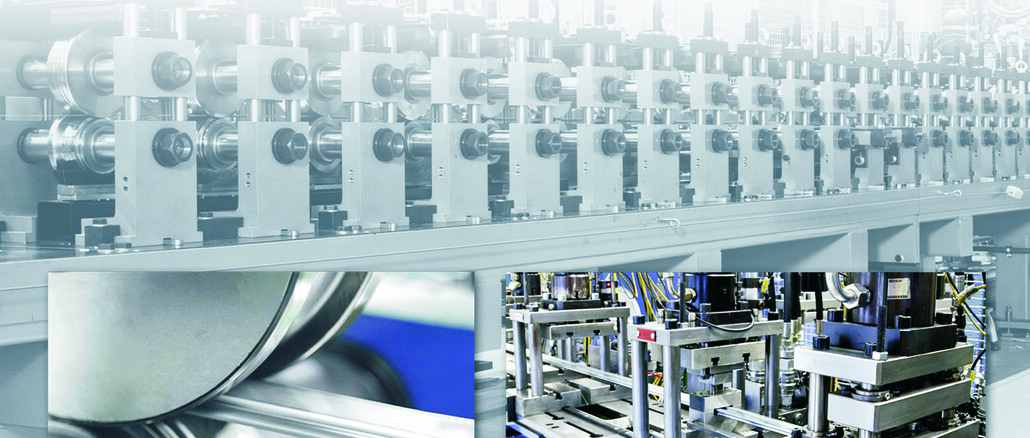

The factory premises at the Urbach location as the headquarters of the Schock Metall Group cover 23,000 sqm with a production area of 11,500 sqm. The first and most important production step is roll forming. Precision profiles for telescopic slides and other products are manufactured on roll forming lines developed in-house and further processed with integrated punching, bending and joining processes.

In accordance with the Schock motto “reinventing motion”, the high-precision roll forming of guide profiles is one of the company’s core competencies. This material-saving and economical production process forms the basis for the innovative and technically sophisticated products, which is also reflected in the numerous awards received by Schock customers. For example, an Italian kitchen supplier recently received the Interzum “Best of the Best” award for its new corner cabinet pull-out system.

Consistently high delivery performance in the European production network

A significant milestone in the company’s history was the establishment of the Latvian logistics, manufacturing and assembly site FTS Baltic SIA in Liepāja, Courland, in 2019. In the meantime, 250 employees work here in two-shift operation. In addition to powder coating and the assembly of telescopic slides, the plant also offers Schock customers production services and component manufacturing as an extended service portfolio.

In July of this year, the Schock Metall Group also carried out a holding certification at all production sites for the first time. The certified range of services includes the development, manufacture and sale of ball bearing slides, special profiles and assemblies, the production services of powder coating, assembly and component manufacture as well as worldwide logistics.

Interview

Three questions for Martin Schock, who is the second-generation CEO of the company:

What constitutes the brand essence of Schock Metall?

Schock Metall has always had unique selling points in specific product characteristics. This includes the important topic of colour, which fulfils both design and corrosion protection requirements in our products. The powder coating of telescopic slides offers our customers real added value in the form of durable and visually appealing products. Strategically, we have repositioned ourselves since the beginning of the 2000s and defined our target markets by establishing industry competence centers. Today, we focus on clearly defined target customers and growth industries.

Where does the company stand today?

First of all, it is important for me to emphasize that we have always supplied our customers throughout the Corona crisis, with no plant closures and no material shortages. With our European manufacturing network, we have a functioning supply chain and will therefore continue to serve our customers reliably in the future.

Due to the new corporate structure since July 2020, we are economically and financially healthy and powerful. Our company is liquid and free of bank financing. The focus of our industry on kitchens and household appliances also brought us significant sales growth, especially during the Corona crisis.

What development are you aiming for in the next 3 to 5 years?

Our objective is to further establish Schock Metall as an innovative company in the Living, Household Appliance and Automotive markets and to continue to grow especially in Europe and the USA. New developments such as the Air motion smooth-running guides contribute to this.

In the “Living” segment we focus on wire basket solutions and functional furniture. In the white goods sector, we cover the entire “cold – hot – wet” range with customised solutions, right through to complete systems in the oven sector.

And in the automotive industry we are perceived as the innovation leader in car and truck interiors. In all segments, we aim to increase value creation by manufacturing complete assemblies and kinematics solutions to offer our customers advantages in their procurement logistics and supply chain management.

Our Urbach site, which celebrates its 50th anniversary this year, is the central plant for roll forming and series start-up production for all new products. We consistently invest in new technologies here, from roll forming to modern joining and assembly technology.

Our greatest intellectual capital lies in the minds of our employees. Our employees with their creativity and their readiness for action are the decisive factor for us as a medium-sized company to be successfully present on the market also in the future.

Web:

www.schock-metall.de