This year’s Euroblech exceeded the expectations of the Profilmetall Group. At the booth, the company representatives registered a noticeable increase in interest in the roll forming process, which was also expressed by visitors from other European countries.

This year’s Euroblech exceeded the expectations of the Profilmetall Group. At the booth, the company representatives registered a noticeable increase in interest in the roll forming process, which was also expressed by visitors from other European countries.

It is true that the advantages of profiling, particularly in terms of material and energy efficiency, are often still unknown. “However, there is a great willingness to rethink one’s own production and to consider substituting existing processes in view of the challenging framework conditions,” reports Simone Weyerich, Managing Director of Profilmetall Engineering GmbH.

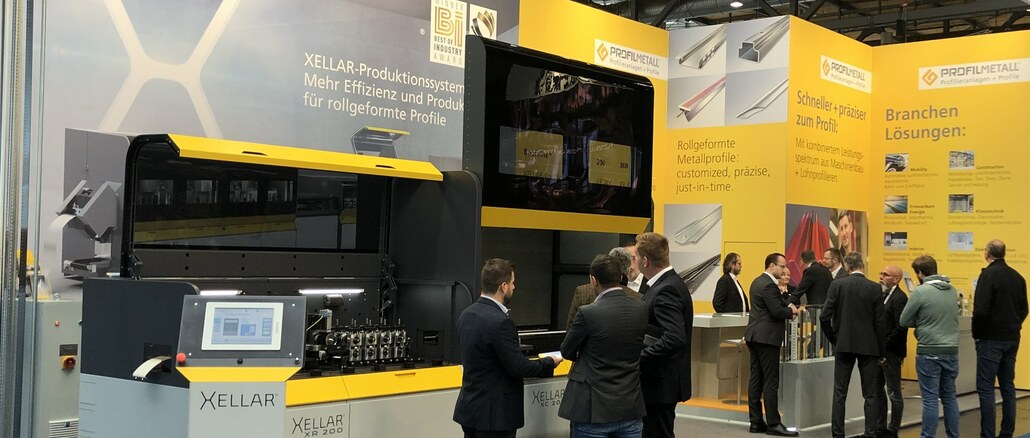

The contacts were more numerous than expected, very targeted and of consistently high quality. In addition, he said, a contract was signed at the booth for the development of several Xellar profiling lines and a supplier agreement.

Focus on trade fair innovations

The new Xellar 400 profiling line, the revised and energy-saving “Xellar Cut” cut-to-length module for sheet widths up to 200 mm, and components for roll forming higher-strength and high-strength steels also met with great interest.

Xellar 400 is designed for sheet entry widths up to 400 mm and thicknesses up to 3.5 mm and extends the existing range of Xellar rollforming lines for coils up to 200 or 300 mm wide upwards. The modular Xellar systems consist of freely combinable production cells for roll forming, punching, cutting to length and laser welding, which can be quickly and easily exchanged as required. This makes them flexible to use.

Energy saving cut to length module

Various, easily interchangeable drive units are available for the “Xellar Cut” cut-to-length module, allowing users to respond to a wide range of cutting tool requirements. The energy-saving servomechanical design attracted particular attention at the booth. There are also servo-hydraulic, hydraulic and pneumatic systems.

© Profile metal

Higher and high-strength steels: Roll-formed sections as an alternative

The concepts for processing higher-strength and high-strength steels presented by Profilmetall were also in demand. Visitors from the automotive and e-mobility sectors in particular came to the booth to find out more. “OEMs are currently questioning their production of crash-relevant components such as battery boxes, bumpers, and frame and structural components, which they want to produce more cost-effectively using less material and energy,” explains Andreas Enderle, managing director of Profilmetall GmbH.

Roll-formed profiles made of very thin-walled steel offer an alternative to aluminum components. They can be roll-formed in a very stable manner, even with high volumes and complex geometries, so that weight is saved during profiling. As a rule, additional production steps and pre-processing are also possible inline and without interrupting production, so that energy is also saved.

Customers benefit twice

Customers interested in profiles made of higher-strength and high-strength steels can benefit from the Group’s services in two ways. Profilmetall GmbH from Hirrlingen, district of Tübingen, takes over the rapid contract manufacturing of components. At the same time, Profilmetall Engineering GmbH from Marktheidenfeld in Main-Franconia offers them efficient and flexible profiling systems for their own production with Xellar.

About the Profilmetall Group

Profilmetall Group is the specialist for roll formed metal profiles and roll forming lines. It is the only supplier in Germany to offer the entire rollforming know-how in one company group with series production and tool and machine construction. This includes Profilmetall GmbH in Hirrlingen, Tübingen County, and Profilmetall Engineering GmbH in Marktheidenfeld, Main-Franconia. The range of services includes the development, design and manufacture of roll forming lines, special machines and individual roll forming tools including comprehensive services as well as the series production of ready-to-assemble metal profiles on behalf of customers.

The innovative medium-sized family business with 110 employees has almost fifty years of experience and cooperates with numerous scientific institutions. The Europe-wide customers come from many industries – from window, switch cabinet and automotive construction to the furniture, electrical and solar industries as well as building, warehouse and medical technology. In 2021, Profilmetall targeted sales of 19 million euros.