PEM, a pioneer in fastening solutions, introduces its latest development, RVTB captive threaded rivet nuts designed for exceptional performance when used in thin sheet metal.

RVTB rivet nuts, as well as PEM, RAB, RABS, RMAB and RMABS, offer robust and reusable threads in ultra-thin sheet metal, making them suitable for a wide range of industries and applications.

As main features and advantages PEM states:

➢ Versatile use: Designed to create strong, reusable threads in sheet metal that is often too thin to thread. The PEM-RVTB rivet nut can be installed in materials with different thicknesses, which makes it very versatile.

➢ Edge-friendly installation: Allows installation close to the panel edge without causing deformation and offers flexibility in design and mounting.

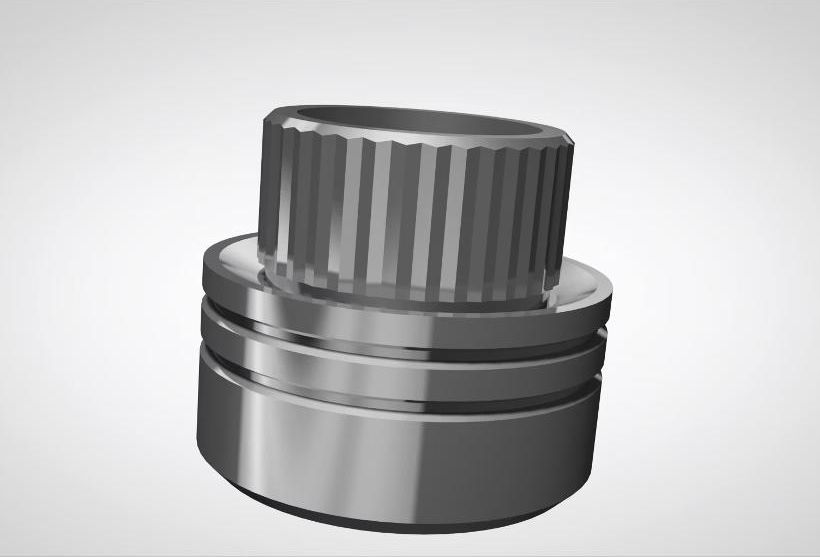

➢ High pressure and torque stability: Thanks to their serrated shank, PEM-RVTB rivet nuts offer excellent pressure and torque stability and ensure reliable anchoring in demanding applications.

➢ Compact design: For applications with limited installation space, the mini rivet nuts, PEM type RMAB and RMABS offer the same performance features in a smaller, more compact format.

➢ Wide range of sizes: Both round and mini rivet nuts are available in thread sizes from M3 to M5 in both mild steel and stainless steel variants.

➢ Paint compatibility: Can be installed in painted chassis materials without compromising quality.

➢ Versatile material compatibility: The ability to install the PEM RVTB in composite and non-ductile materials makes it suitable for a wide range of industries and applications.

“The introduction of rivet nuts completes our product offering for industrial manufacturing operations,” said Mary Ann Fleming, president of PEM Europe. “They allow installation in panels with excessive material hardness where conventional self-clinching fasteners cannot be installed. Rivet nuts can also be used for non-ferrous metals such as aluminum alloys, copper and brass, or for non-metallic materials such as plastic and asbestos. Rivet joints are free of thermal aftereffects because no heat is required in the joint.”

Fleming continues, “We go one step further to ensure joint security and provide absolute confidence in the installation process when a Haeger or Pemserter installation machine is used for automated assembly. Manufacturing companies have consistently expressed a desire for automated installation of rivet nuts, and we have met that request.”

Web:

pemnet.com