This year Kohler Maschinenbau GmbH will again be present with a booth at the Blechexpo trade fair in Stuttgart. Visitors can look forward to exciting new products in the field of both parts levelers and strip levelers.

Kohler not only ensures process optimization through flat and low-stress plates, but also through contemporary coworking. The loading and unloading of small parts is an activity that can be optimally automated with a cobot, especially for large batch sizes. Because while the actual part straightening often takes only a few seconds, the handling of the parts during the entire straightening process often takes the most time.

Solution for the automated straightening of parts

Therefore, the use of a cobot brings numerous advantages: In bin picking or “reaching into the box”, the cobot can use a 3D camera to remove parts that are in a completely chaotic arrangement in a container and feed them in the correct orientation for further processing. Bin picking thus replaces tedious operator tasks, while skilled personnel can concentrate on their core competencies during this time. A cobot that enables close cooperation with humans without a separating protective device can also take over an additional work shift or, if necessary, compensate for anticipated staff shortages.

Here, Kohler offers an automated parts handling solution for parts levelers that not only increases efficiency, but also reduces costs during operation at the same time. A completely relaxed way of working is thus programmed.

© Kohler

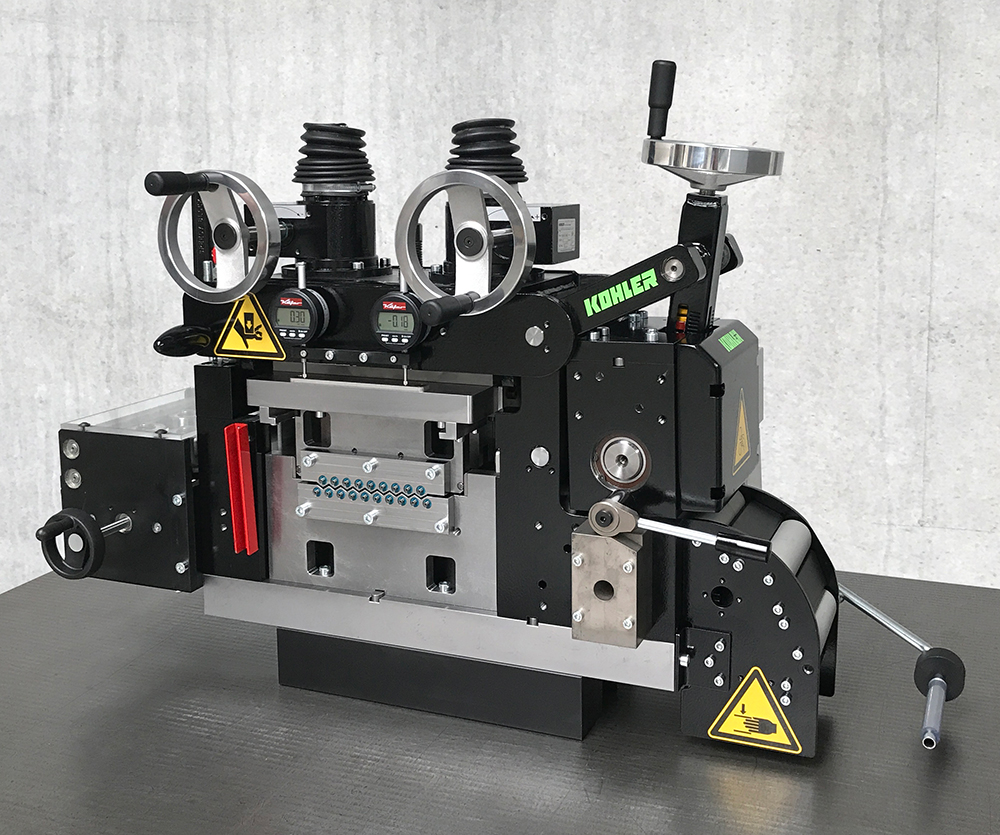

Precision Straightening Machine for Electrical and Electronic Strip Material

Kohler has developed a compact precision leveler specifically designed to meet the demands of manufacturing connectors, plugs and electronic components. Users benefit from optimum straightening results even with thin coil material. The straightener has been equipped with 19 hard chrome plated straightening rolls supported by a large number of back-up rolls, providing high rigidity. The small roll diameter ensures that even the thin strips commonly used in the industry can be precisely straightened.

The CPL as a complete system with horizontal decoiler for different coil weights can also be examined at the Leicht Stanzautomation GmbH booth.

Background

Kohler develops and produces parts straightening machines and strip feeding systems for presses and automatic punching presses as well as cut-to-length lines, for example for steel service centers, mechanical engineering companies or for the automotive industry. In its modernly equipped straightening center, the company straightens plates on a contract basis and carries out straightening tests. Kohler straightening machines achieve straightening results that increase quality and productivity in sheet metal processing. The efficiency and reliability of Kohler’s machines ensure sustainable profitability in ongoing operations. The company reduces the energy and resource consumption of its machines for the benefit of the environment. The headquarters with its own production is located in Lahr in southern Germany. Kohler also has sales and service locations in Shanghai (China), Moscow (Russia) and Salt Lake City (USA). In total, the specialist has implemented more than 6,700 reference projects worldwide in 60 years. Kohler focuses on the needs of its customers in development and project management, always with the goal of working together reliably in a long-term partnership.

BlechExpo

Hall 5 Booth 5502 (Kohler)

Hall 6 Booth 6207 (Light)

Web:

www.kohler-germany.com