Foba was on site at the International Manufacturing Technology Show IMTS in Chicago/USA (September 9-14, 2024) with three laser marking systems.

The main focus is on the lightweight and space-saving integration of the new UV laser head into a Foba M1000.

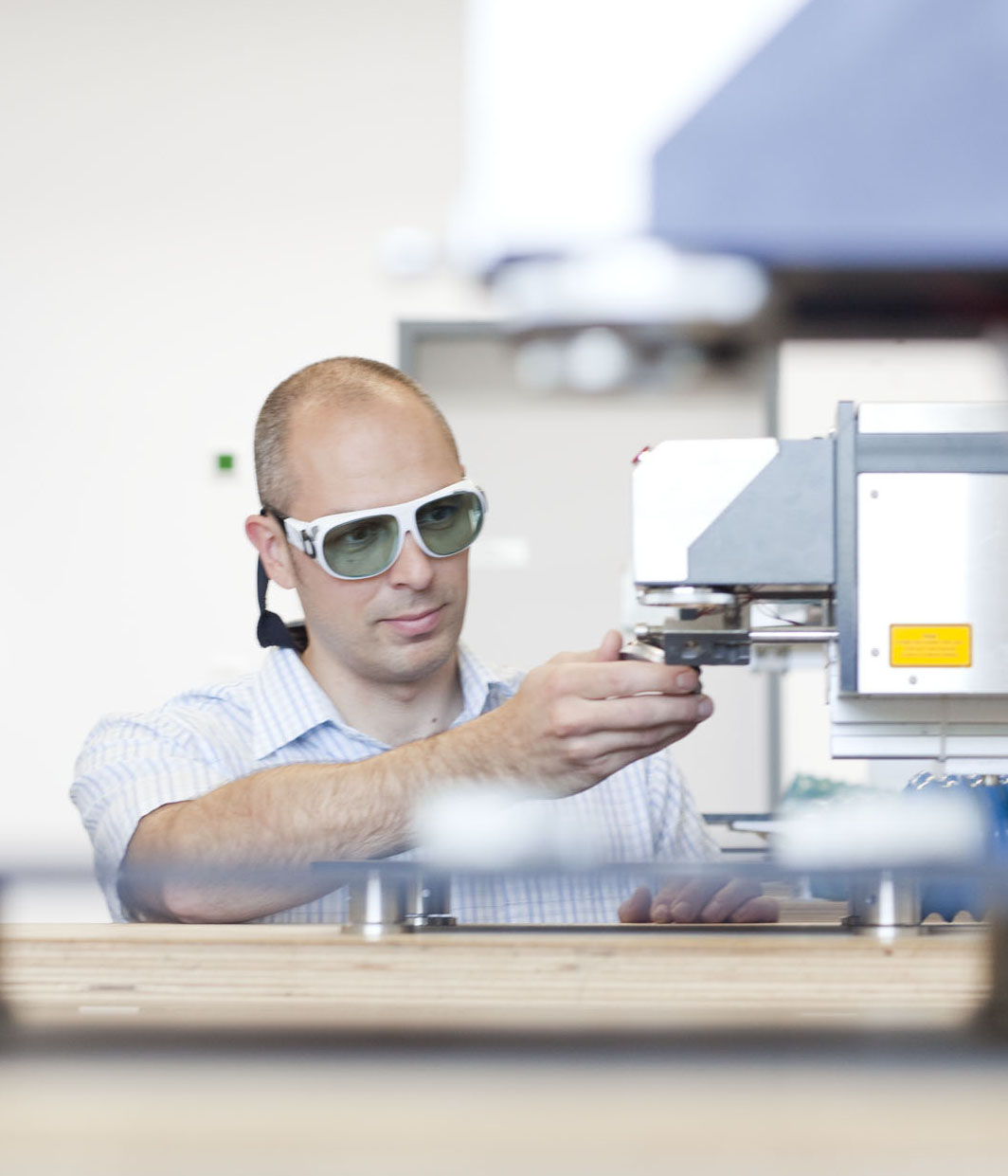

At IMTS, Foba showcased a full range of laser marking, from the largest laser marking workstation M3000 to the compact manual workstation M1000 and the smallest laser marking head in the world, Titus. Each laser system shows different application areas and functions for efficient industrial product marking, from metals to plastics.

© Foba

The latest addition to the Foba product family is the optimized V-Series, which offers higher power and better precision than its predecessors with the 4-watt UV and 10-watt green marking laser, but at a fraction of the size. The laser head is so compact that it can be integrated into the Foba M1000 manual workstation. The smaller size makes it easier to integrate into existing production environments.

“The new V-Series shows its strength above all in the marking of plastics and composites,” says Philipp Febel, Director Product Strategy & Customer Experience at Foba, “and is a sustainable alternative to other marking technologies such as continuous inkjet or pad printing.” In contrast to these marking technologies, the marking lasers require hardly any consumables and therefore minimize waste and operating costs.

In live demonstrations on the M3000 laser marking machine, visitors will see the deep black marking of stainless steel in combination with the Mosaic feature, which automatically aligns the marking – even on parts that are randomly placed in the marking field.

With the Titus fiber laser marker, Foba will be exhibiting the smallest laser marking head available on the market, according to the supplier.

It is predestined for fast marking in production lines and offers maximum flexibility in terms of integration.

All three systems will be available for live demonstrations at the trade fair stand.