At Schweisstec from October 26th to 29th 2021 in Stuttgart, Cloos will present innovative solutions for faster, more economical and more flexible welding production. The welding specialists offer technologies ranging from entry-level to premium and from manual welding equipment to automated interlinked robotic systems.

During demonstrations in the manual welding area, trade visitors can experience the constantly growing product range of Quineo welding equipment live. The Quineo StarT provides an easy start into the world of modern MSG welding technology. Thanks to the excellent price-performance ratio, users can weld any workpiece at economical conditions.

The high-tech MSG welding power source Quineo NexT convinces with its arc characteristics for high welding quality. The modular design enables a wide range of applications, from the basic welding unit for manual welding to the multi-process welding unit for automated robot welding. In addition, the new Quineo QuesT now complements the portfolio for high-end TIG applications.

The new welding power source has been specially developed for TIG welding processes and is particularly suitable for the most demanding welded joints and the highest quality requirements.

The new Quineo welding power sources are characterized in particular by digital connectivity, maximum energy efficiency and the possibility of integrating new welding processes. Innovative welding processes such as Fine Weld and MoTion Weld as well as new combination possibilities of different processes in one weld seam guarantee high quality and efficiency.

Complex automation solutions: Live circuits into production

“In addition, we make live connections from our trade fair stand to our manufacturing site in Haiger,” says Stephan Pittner, Technical Managing Director. “This allows visitors to learn directly about our complex solutions for automated welding and ask questions of the experts on site.”

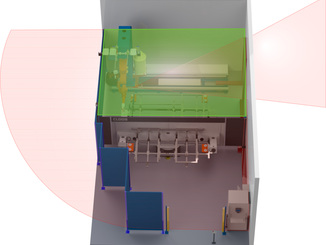

Cloos offers integrated solutions for automated welding.

Thanks to its modular design, the Quirox system enables scalable solutions that are optimally adapted to different applications and individual production requirements. The Quirox system comprises robot technology, positioners, safety technology, software, sensor technology and the interface to the process technology. It is complemented by a comprehensive range of accessories and coordinated services.

Extensive robot range: more than welding

“We now offer more than 20 different types of robots, doubling our range of robots in the last two to three years,” explains Pittner. “It was important to us to provide customers with robotic mechanics for every conceivable application, from small, thin automotive parts to specialized application robots for laser hybrid welding and automated grinding.”

This also increases the degree of automation in upstream and downstream processes. Customers often want to combine solutions for automated welding technology with different manufacturing technologies such as grinding applications in one production line.

Digitization platform for the factory of the future

In addition, Cloos is constantly expanding its range of digital solutions. Increasing digitalization enables optimal control and continuous improvement of manual and automated welding production.

With the C-Gate IoT Platform, users can access real-time information from their sweat production. All data is centrally recorded and processed in the holistic information and communication tool.

This allows users to monitor their production processes down to the smallest detail and control them in a forward-looking manner. It consists of several modules that users can activate depending on their individual digitization strategy – from the manual welding power source to the fully automated production line.

Schweisstec 2021: Hall 7, Booth 7416

Web:

www.cloos.de