Laser power has multiplied in recent years, while demands for precision and quality in laser processes continue to rise. The result: high-power lasers must be measured accurately. Let’s take a look at the methods used to avoid or dissipate extreme thermal loads at the absorber and safely measure laser beams.

Rising Power Levels

High-power lasers are now widely used as tools in various material processing applications. Economically, falling prices per kilowatt of laser power and faster processing times have paved the way. Technologically, a wide range of new laser systems with different wavelengths have been developed, enabling fast and precise processing of novel materials.While welding processes typically use lasers with a maximum output of 8–10 kW, cutting systems today commonly operate with lasers up to 60 kW. A relatively new application—especially in Europe—uses even higher power levels: directed energy systems in defense technology operate with laser powers exceeding 100 kW.

But how can such high laser powers be measured?

© Ophir

Short Measurement Time, High Accuracy

Various methods are used to measure high laser powers: thermal, calorimetric, and the Power-from-Pulse method. The latter is particularly suitable for automated manufacturing environments, enabling fast, repeatable measurements without water cooling.

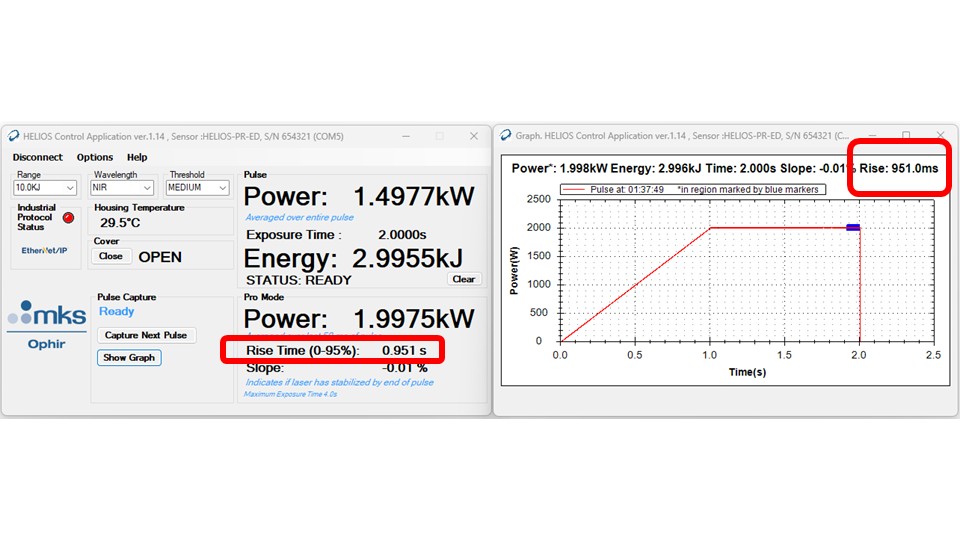

This method is used in the Ophir® Helios product family. These devices measure the energy and pulse duration of individual pulses and calculate laser power with high precision—up to 12 kW. Thanks to the short measurement time, laser beams can be checked directly before use in the process, ensuring that the required power density at the material level is met.

The latest version of the device, showcased for the first time in Europe at Laser World of Photonics, further optimizes the method:

The Ophir Helios Pro power meter now also monitors pulse shape during energy measurement and incorporates this data into the power calculation. This corrects for effects such as slow pulse rise times when the laser is switched on.

© Ophir

Measuring Ultra-High Power

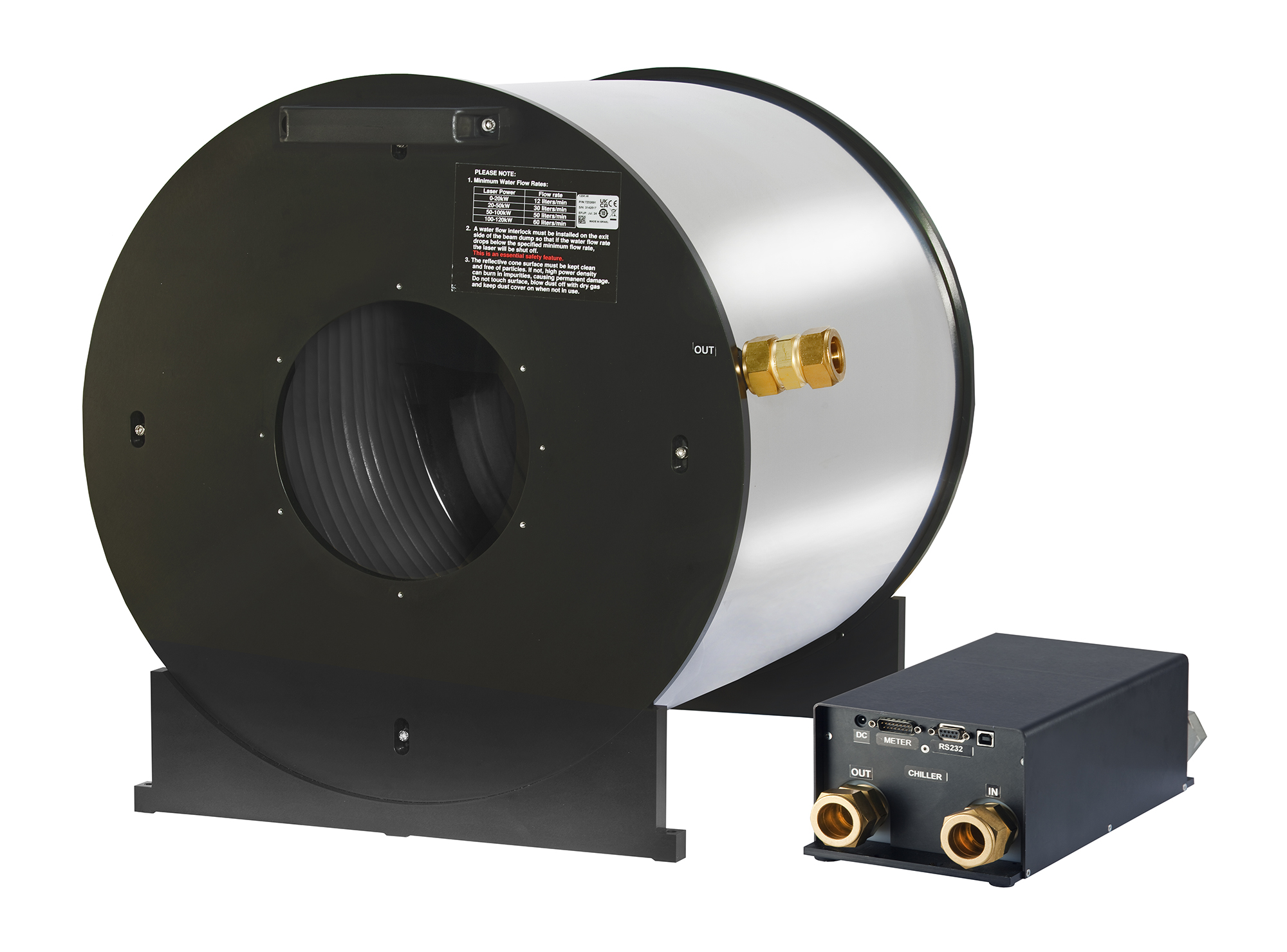

Laser powers well above 12 kW are typically measured calorimetrically. The laser beam heats water inside the measuring device, and the resulting temperature difference is used to calculate the laser’s power.

This principle is used in the Ophir 70K-W power sensor. At Laser World of Photonics, MKS introduced a new version of this sensor, now integrating Power-from-Pulse technology and extending the measurement range up to 100 kW.

This added functionality is especially relevant for developers of High Energy Laser Weapon Systems (HELWS), which use fast, high-energy laser bursts. Purely calorimetric sensors with a response time of 40 seconds cannot capture these bursts.

The unique design of the 70K-W sensor combines precise power measurement and beam dumping in a single device.

Safety at Extreme Power Levels

As laser power increases, so do the safety requirements for sensors. One key factor is low backscatter. While negligible for low-wattage lasers, a backscatter of more than 1% from a 150 kW laser poses a serious safety risk.

Only a few companies worldwide offer sensors in this power class. This year, MKS introduced a new calorimetric sensor capable of measuring laser powers up to 150 kW. The sensor’s backscatter is less than 0.5%.

© Ophir

Comprehensive Beam Diagnostics for High-Power Lasers

Measuring high-power lasers is a real challenge. Power verification is just the first step.

Advancements in lenses and mirrors allow for more precise beam focusing, enabling cleaner cuts with narrower kerf widths. Additional beam parameters such as focus position, focus shift, and beam caustic are critical.

To reliably determine these parameters, non-contact measurement devices like Ophir BeamWatch can be combined with the 70K-W or 150K-W sensors.

Author:

Sven Kern, Regional Sales Manager Ophir I MKS

Web:

www.ophiropt.com