Electric steel specialist Steeltec, a Swiss Steel Group company, has invested around 60 million euros in a new walking beam furnace and other equipment at its rolling mill in Emmenbrücke near Lucerne, Switzerland, making it one of the biggest investments in recent years for the company and the entire Swiss Steel Group.

© Steeltec

The new furnace enables significant efficiency gains in the rolling mill and for its customers and consistently ensures greater sustainability. Higher coil weights and a significantly more homogeneous quality of the rolled steel products are the result. Thanks to high specialization, it is very economical with its gas fuel. It has been in operation since September 2021. As with its predecessor, it is a gas-fired walking beam furnace that continuously heats the billets sourced from Steeltec’s own steel mill.

“With the investment, we are gaining in productivity and quality and can thus meet our customers’ requirements even better. With the previous furnace, which was over 40 years old, we were only able to process steel billets weighing 1.8 t, 11 m long and with a profile of 152 x 152 mm,” explains Dr. Florian Geiger, CEO of Steeltec. “In contrast, the new system currently warms billets weighing up to 2.3 t and 13 m long.”

Sustainability and efficiency increase

The longer and heavier products result in less process waste for customers, both during rolling and further processing. In addition, thanks to the longer raw materials, customers’ machines need to be reset less often for the same amount of material. In the rolling mill, the annual steel throughput will increase by around 5,000 t as a result of the longer and heavier billets alone. In total, the new furnace can heat a maximum of 150 t of steel per hour to 1300°. The rolling mill processes around 200 different types of steel at temperatures between 1100° and 1250°.

© Steeltec

Ecologically in particular, the new furnace is a considerable step forward. Despite its increased capacity and larger volume, it requires around 13 percent less gas than the old plant. The process waste heat from the furnace is first used to preheat the billets after they enter the furnace. Afterwards, as much of the remaining waste heat as possible is decoupled into the district heating network of the city of Lucerne. Overall, Steeltec is reducing its CO2 emissions by just under 10 percent a year with the innovations in the rolling mill.

Frank Koch, CEO of Swiss Steel Group Holding AG, explains: “The investment is trend-setting for us: We are thus following the Swiss Steel Group’s strategy of positioning itself as a leader in the field of sustainable steel production.” Steeltec is already one of the largest recycling companies in Switzerland, processing around 680,000 t of steel scrap annually into carbon, stainless and free-cutting steel. Around 60 percent of the input scrap comes from Switzerland, the rest from neighboring countries.

“As with the Swiss Steel Group, Steeltec is also aware of its responsibility towards the environment and society,” says Dr. Florian Geiger. “Increasing efficiency from steel melting to bright steel production has always been part of the company DNA and has made us one of the most environmentally efficient steel producers in our class. Across all production areas, Steeltec’s carbon footprint is around 90 percent lower than that of the global industry average.”

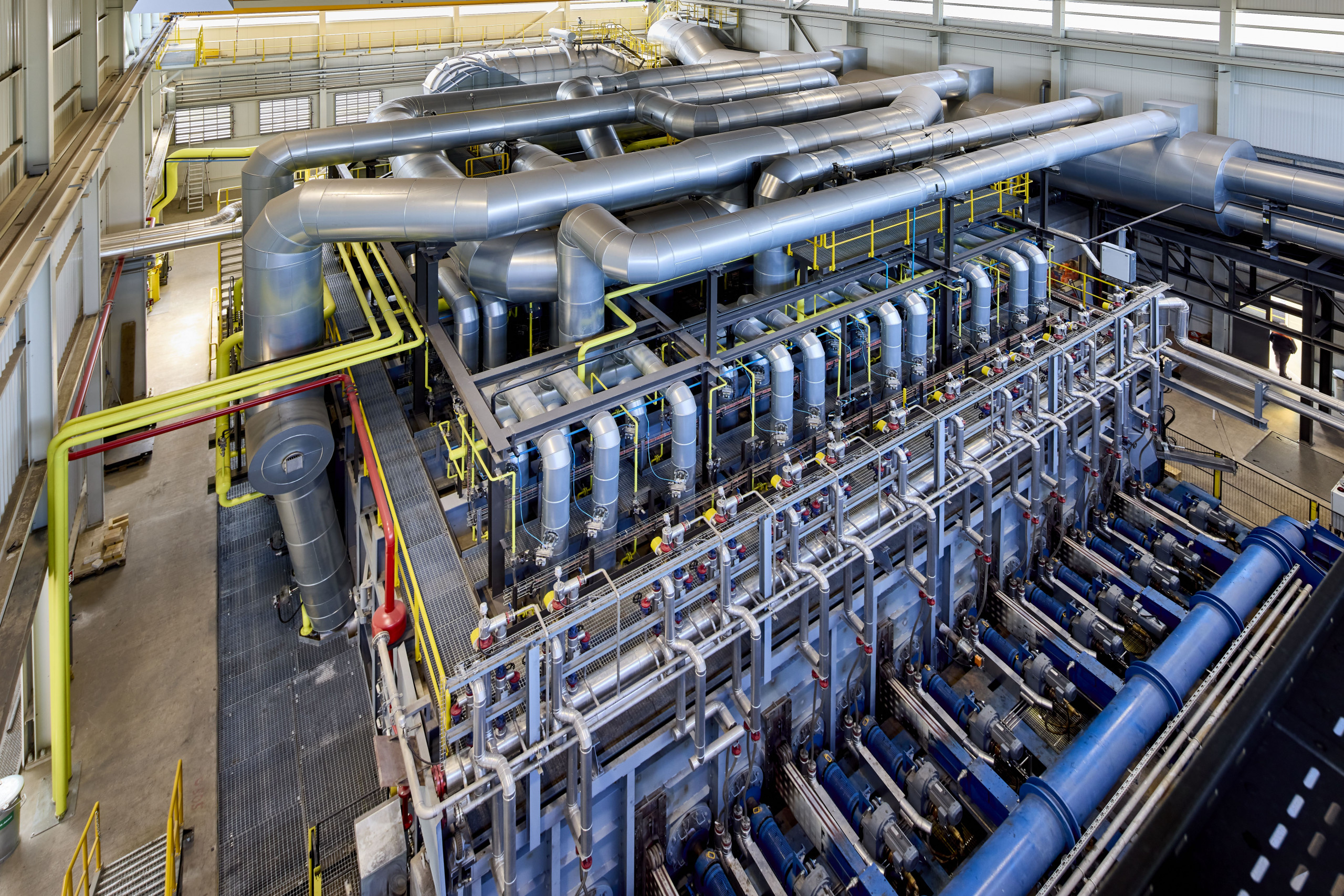

Additional modernization measures

The implementation of the new walking beam furnace has triggered further modernization steps in Emmenbrücke. In addition to the furnace and the new induction system, Steeltec has purchased two new Garrett reels and a controlled cooling system for the finished rolled wire coils. The diameter of these rolled products is up to 50 mm as round or hexagonal sections and are reeled with the reels into coils up to 1440 mm in diameter and weighing a maximum of three tons. In the downstream controlled cooling system, the rings are cooled in a controlled manner at 16 positions from below with blown-in air. Cooling is slow, uniform, controlled and can be adjusted individually for each steel grade.

Further investments are planned

The latest investments are a commitment to the Emmenbrücke site and to Switzerland as an industrial location. At the same time, they are preparing further modernization steps for the plant. The new walking beam furnace was moved back by 100 m. This creates space for an expansion of the rolling mill and thus for even more product variety and even greater flexibility in the future.

For Steeltec, it is important to always stay on the cutting edge of what is technically feasible: “Our customers appreciate our high flexibility, high delivery reliability and Swiss punctuality. Together with our customers, we also solve very short-term challenges at a high quality level,” says Dr. Geiger. “We want to retain and further expand this advantage of flexibility and wide product variety.”

About Steeltec

Steeltec produces carbon, stainless and free-cutting steels as well as special bright steels for the automotive, engineering, hydraulics and apparatus construction industries. The largest production site is Emmenbrücke in Switzerland with a steel mill, a rolling mill and two bright steel mills and around 750 employees. A further 250 people are employed in production and sales units in Germany, Denmark, Sweden and Turkey. Steeltec recycles 650,000 tons of steel scrap annually for the production of long steel products. This corresponds to around half the volume of scrap generated in Switzerland and makes Steeltec one of the largest players in the Swiss circular economy. The company is part of the Lucerne-based Swiss Steel Group, which employs around 10,000 people in more than 30 countries.

Web:

steeltec-group.com