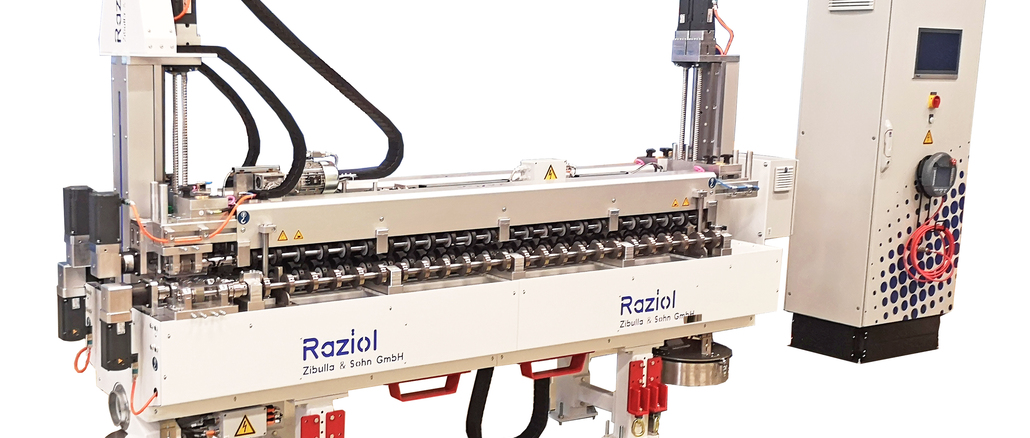

Raziol Zibulla & Sohn GmbH has developed a brush cleaning system upstream of oiling for cleaning moulded blanks in particle-sensitive products such as outer skin parts. The cleaning unit offers users a convenient solution for efficient material cleaning and can be optimally combined and integrated in the process with the proven Raziol oiling technology and the associated lubricants.

Particle-free surfaces are becoming increasingly important for the manufacture of high-quality products. Particles and dust can lead to expensive quality losses, rework or scrap during the forming process. To avoid these errors, the integration of high-quality linear twin brushes with Wandres brush technology in the Raziol brush cleaning system provides the prerequisites for clean surfaces. Particle-related damage to the tool or the blank is thus avoided and, in addition to the service life of the tools, also increases the quality of the end product. Cleaning widths of up to 4,500 mm are possible in order to effectively remove interfering particles from the circuit board on both sides with the new cleaning system. In this process, the Raziol brush cleaning system not only removes the disturbing particles, but also homogenizes the pre-oiling on the material to be cleaned.

© Raziol

The cleaning system with a central control and supply unit offers an application-oriented solution for efficient material cleaning in the process. In the construction and design of the new system, proven and field-tested Raziol system technology was used. In addition, maximum ease of maintenance and optimum platinum transport characterize the new Raziol brush cleaning system. Driven transport and pressure roller shafts ensure reliable and optimum platinum transport through the cleaning unit. An automated crash detection system prevents damage to the system in the event of incorrect positioning or unacceptably high transverse curvature of blanks by lowering the upper and lower crossbars.

Operation is either via the touch display on the central control unit or a user-friendly handheld and can also be integrated into a downstream Raziol lubrication unit if required. Due to its slim and ergonomic design, the Raziol lubrication system is well equipped for use in press shops and can also be integrated into existing production lines.

About Raziol

Raziol Zibulla & Sohn GmbH has stood for quality in lubrication technology for over 80 years. Roller lubricators, spraying systems, lubrication control systems, dosing devices as well as high-performance forming oils are among the products developed and designed in-house. In addition, worldwide service and commissioning by our own employees characterise the high quality standards of Raziol Zibulla & Sohn GmbH.

Web:

www.raziol.com