A clean surface ensures smooth production processes and first-class product quality. Effective cleaning of product surfaces reduces the reject rate and avoids expensive machine downtime.

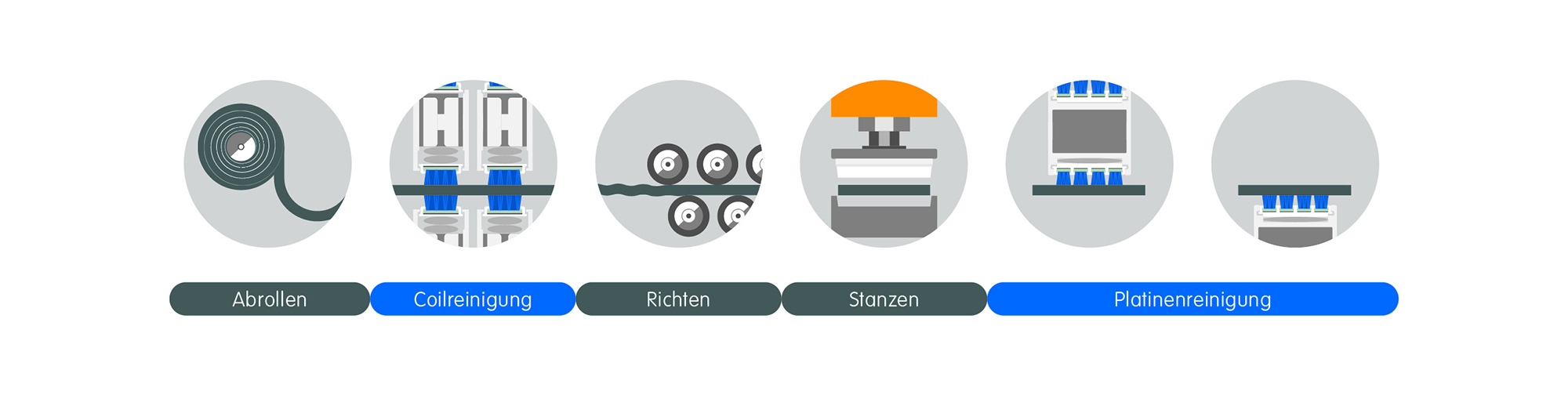

The compact and energy-efficient cleaning systems from Wandres can be easily integrated into existing production lines and are used at several points along the cutting and press line. Sheet metal strips made of steel, stainless steel, aluminum or non-ferrous metals as well as blanks for outer skin or structural parts can be reliably cleaned on both sides with the cleaning machines in continuous industrial operation. From high-speed coils to blanks or conveyor systems, Wandres offers the right low-maintenance cleaning solutions.

© Wandres GmbH

Before straightening, sheet metal strips are cleaned on both sides by two Sword Brushes. Even a sharp-edged or wavy strip can be thoroughly cleaned at high transport speeds. The changeover from a coil with dry lubricant to an oiled sheet metal strip works smoothly and without any changeover time.

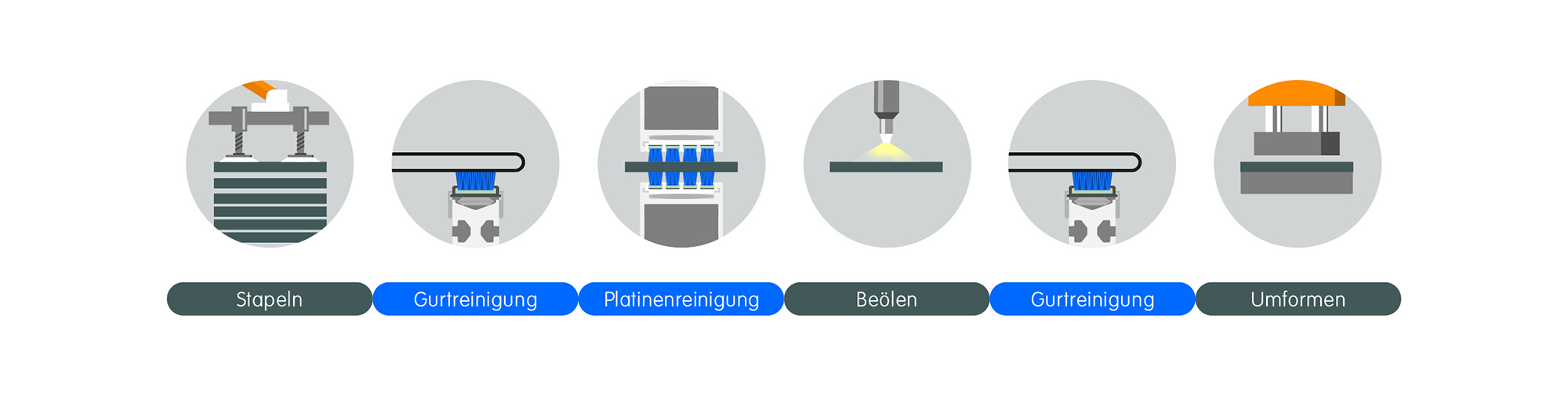

After the cutting press, laser blanking or punching, the sheet metal blanks are first cleaned from above and then from below. This prevents any loss of quality when they are ejected onto the stack of blanks.

All particles adhering to the outer skin blanks or structural parts should also be removed before entering the press. This prevents damage to the forming tool and the blanks and significantly reduces the reject rate. Blanks made of steel and aluminum can also be cleaned on both sides in alternating operation with high cleaning quality and reproducible results.

The compact cleaning machines can be combined with a lubrication system and can be easily integrated into any line. Cleaning conveyor belts is also essential: the Sword Brush removes particles and contaminants in continuous operation, preventing them from being carried over to the already cleaned sheet surface.

Web:

www.wandres.com