In addition to other innovations, Röder Maschinenbau will be presenting the new PFZ Ultimate series as an important milestone at Blechexpo. With it, the company is expanding its portfolio with a CNC profile processing center that is consistently tailored to the increasing requirements in profile and panel processing.

© Röder

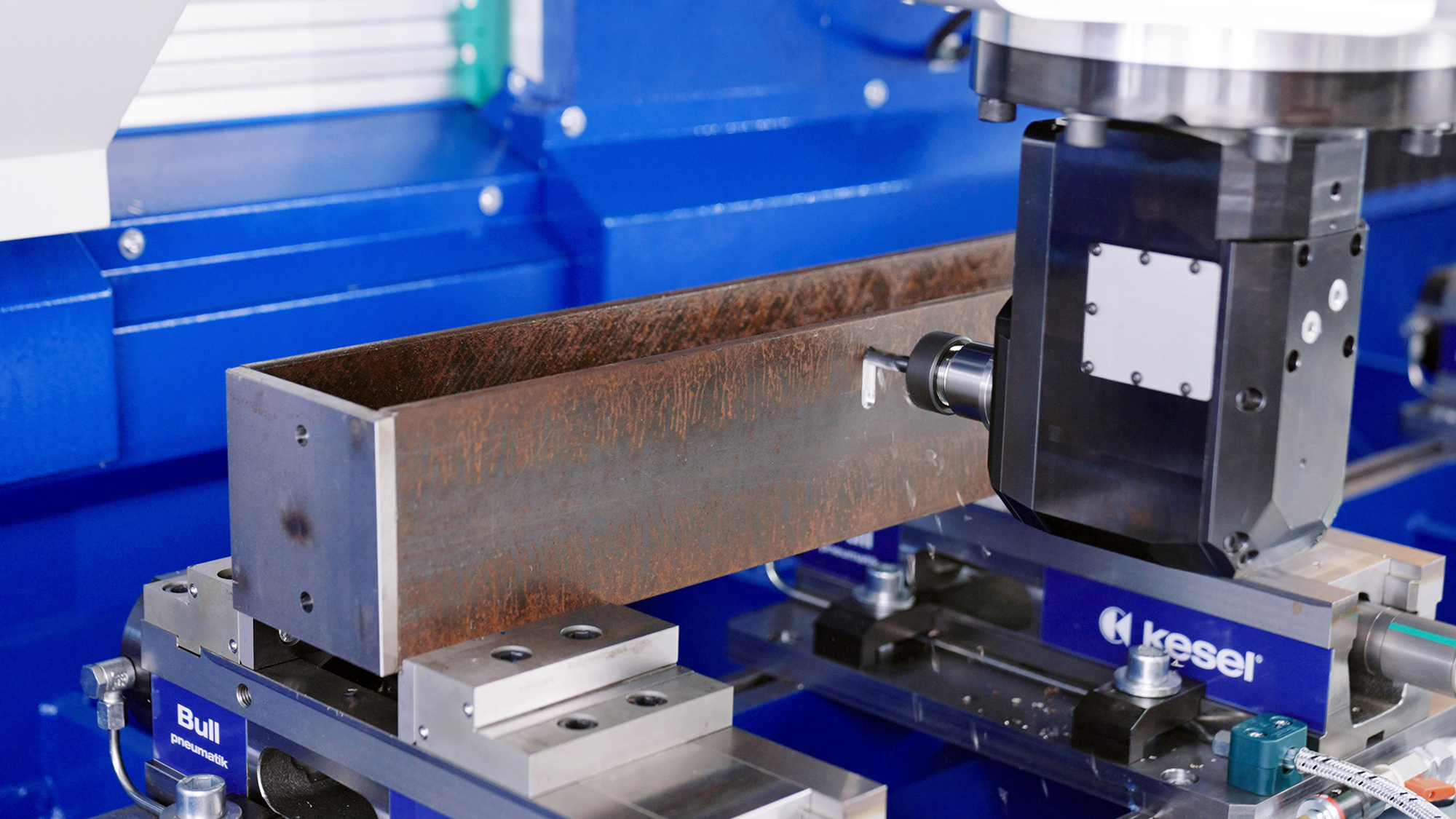

A key feature of the new machine is the “WK360” angle head, which has been specially adapted to customer requirements. It is integrated into the machining process via the fourth axis and enables complete 5-sided machining of workpieces and profiles up to 12 meters in length – without time-consuming reclamping. The stepless 360-degree swivel capability ensures flexible access to all relevant profile sides. “The most striking feature is certainly the angle head, which has an automatic tool change function and enables extensive 5-sided machining. This allows our customers to significantly reduce their processing time,” explains Managing Director Erwin Röder.

Automated complete machining

The angle head not only performs milling and drilling operations, but also automatically changes its tools from its 10-position magazine. This allows different machining steps to be combined in a single pass – a clear advantage for precision and process reliability.

Flexible clamping technology and work processes

.

© Röder

The PFZ Ultimate is designed to securely and efficiently fix different workpieces – pressure-adjustable, controlled vices adapt flexibly to different processing scenarios. Pendulum operation is also possible: while loading is taking place on one side, processing is already underway on the other. This reduces downtimes and increases throughput.

Extended machining areas

In addition to profile processing, the PFZ Ultimate also covers panels and complex special profiles. The working area has been specifically enlarged for this purpose: The machining range of the Y-axis extends up to 800 mm and the Z-axis up to 550 mm. The PFZ Ultimate therefore offers additional travel for large-format components. Solid construction and high-quality machine components ensure precision and durability.

Systematic operation

Röder continues to rely on its long-standing partner Heidenhain for the control system, now with the new TNC7 Basic. It clearly displays all work steps and allows intuitive programming directly on the control or using various CAD-CAM programs. “Our customers want to produce faster, reduce non-productive times and machine larger components at the same time. We are responding to this with more automation and greater flexibility in machining,” summarizes Erwin Röder.

© Röder

Variants and user sectors

The PFZ Ultimate is available in various sizes: PFZ 4000, 6000, 8000, 12000 as well as in special sizes according to customer requirements. Röder thus offers solutions for a wide range of applications – from smaller components to long profiles made of steel, stainless steel or aluminum. Typical areas of application for the PFZ series include steel construction, hall construction, bridge construction, façade construction and specialized metalworking and metal construction companies.

The Röder service and application team promises to provide users with fast and reliable commissioning, training and individual support.

Background

Röder Maschinenbau GmbH, based in Amstetten, has been developing technical solutions for mechanical engineering for over 25 years. The medium-sized company combines sound engineering with a high level of vertical integration and offers customers customized machines for a wide range of applications. In mechanical engineering, the portfolio includes sheet metal cutting systems, profile processing machines, brushing and deburring machines as well as special machines in these areas. Röder machines impress in sheet metal and metal processing with their efficiency, durability and user-friendly controls. With many years of expertise, a strong development department and close cooperation with users, Röder Maschinenbau develops technologies that simplify and accelerate work processes and improve quality.

Blechexpo Hall 7, Stand 7225