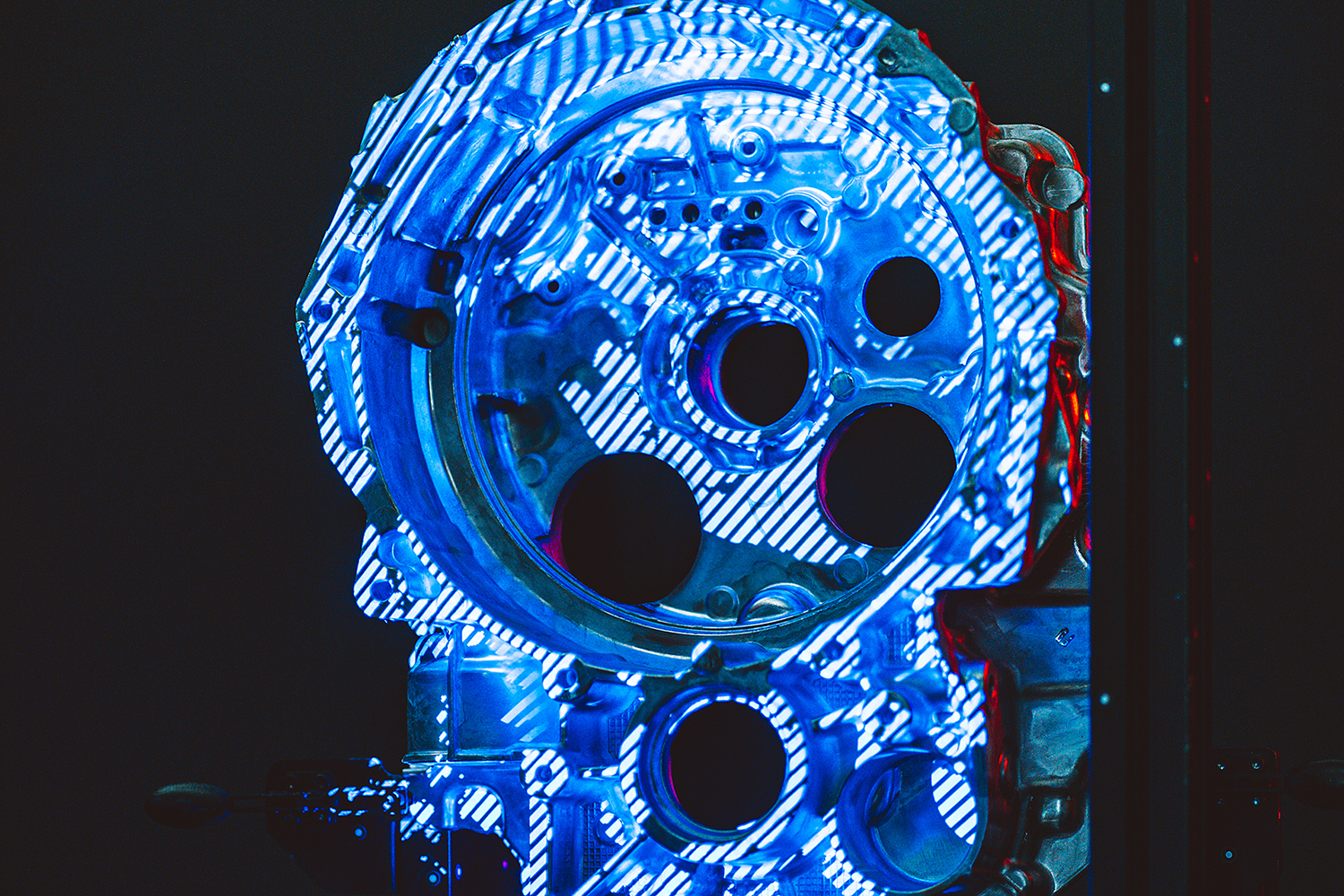

Don’t be confused by the fact that, apart from the holding devices, you are not looking at sheet metal parts but die-cast parts. After all, there are high quality requirements everywhere, especially in the automotive industry. And quality assurance should be thorough, reliable and fast everywhere.

© Zeiss

By 2030, Volkswagen plans to offer 70 percent of all cars produced as fully electric vehicles. Despite the enormous change in the product portfolio, one thing remains the same for Volkswagen as it has for over three quarters of a century: “Our components must meet high quality standards, regardless of whether they are combustion engines or electric motors,” postulates Holger Giersberg, sub-department head for quality assurance foundry and machining at the Volkswagen plant in Kassel. The foundry there produces cylinder crankcases, gearbox housings and housings for electric motors, among other things.

Optimized processes with automated and tactile measurement technology

In three-shift operation, the quality assurance department checks almost 200 delivered components every day. In addition, special measurements are carried out on an ad hoc basis, for example for newly launched products.

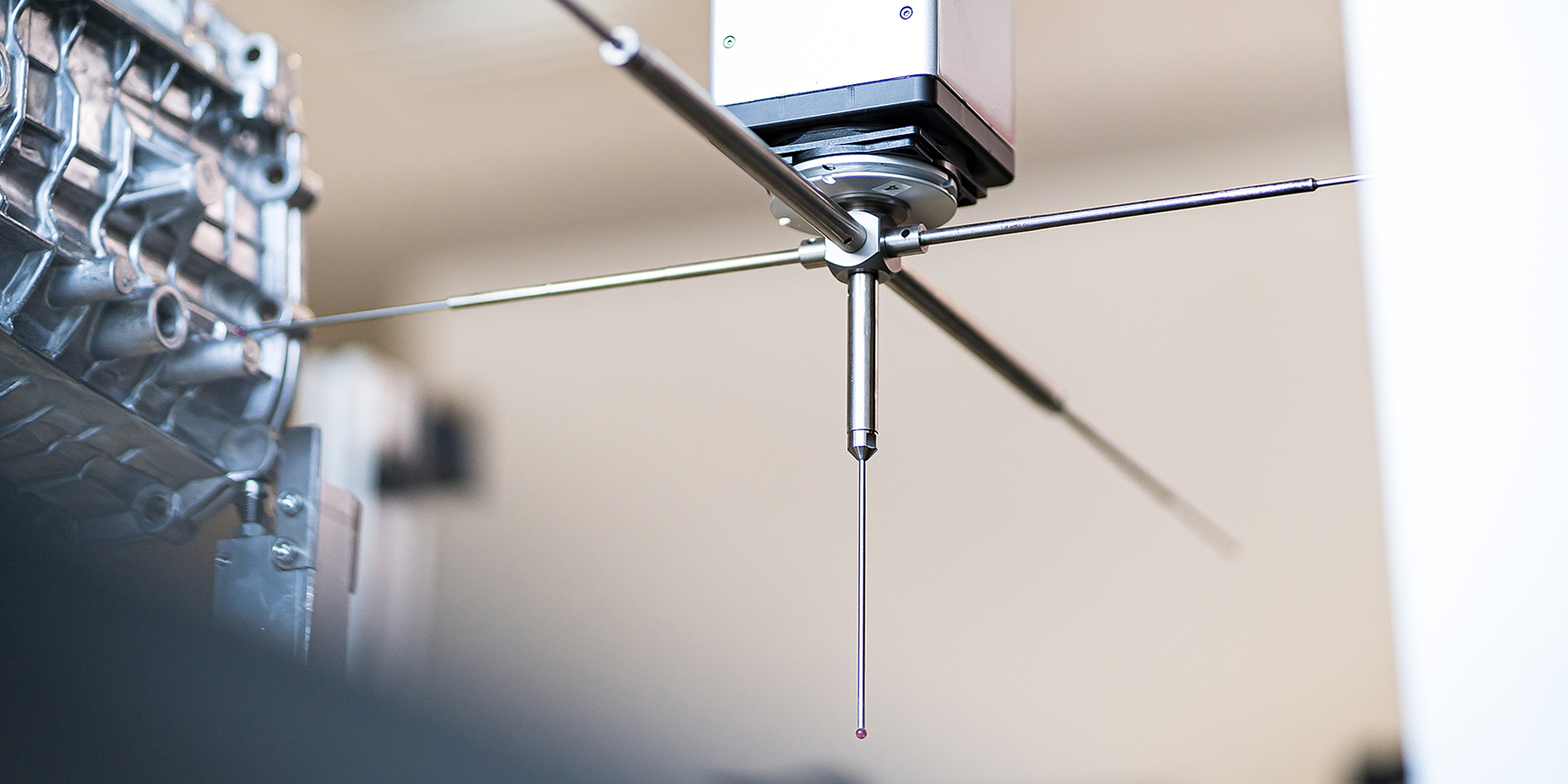

Volkswagen in Kassel has been relying on Zeiss Prismo coordinate measuring machines (CMMs) for many years. In order to shorten the throughput time and at the same time obtain more information in the production process, Volkswagen also installed a Zeiss ScanBox: an automated optical 3D measuring machine that interacts with an automatic loading system from the Zeiss Integration Series with 14 set-up stations. The result speaks for itself: “The flexible networking of optical and tactile measurement technology results in a capacity gain of 30 percent,” reports Holger Giersberg.

Christian Kammer

Automated system combines optical and tactile measurement technology

In a large room in the foundry, the cast parts delivered are ready for inspection. The first step is a visual inspection, then the components are x-rayed. Finally, the quality assurance staff measure the components in a system with several CMMs from the Zeiss Prismo family and also with the Zeiss ScanBox optical 3D measuring machine. “We inspect at least one component from each die casting machine per shift, which means 64 or more inspections in an eight-hour period,” explains Gerd Guhde, Quality Assurance Planner at the foundry.

Before the new complete solution from Zeiss was implemented, the employees had processed their inspection plans using three Zeiss Prismo CMMs and a manual loading system alone. “The process was not yet optimal, as employees had to keep waiting at the system until it was their turn to work on ‘their’ component,” explains Gerd Guhde.

© Zeiss

Faster and easier to achieve a more comprehensive result

The utilization of the available measuring machines could be optimized with this system setup. The speed and quality of the measurement results has also improved: “Another advantage is that we can quickly record important measurement data optically in a single process and supplement missing data with tactile measurements,” explains Rene Bednar, measurement technology inspector in the foundry’s quality assurance department. “This allows us to quickly obtain a complete measurement result for each component and detect errors at an early stage before they have a negative impact on the rest of the production process.”

In addition, thanks to the networking possibilities of Zeiss measurement technology, all the results of the optical and tactile measurements are now summarized in one report. The Zeiss PiWeb reporting and statistics software with additional integrated false color display is used for this purpose. The system can also be operated without restriction by employees without metrological knowledge.

Christian Kammer

Mastering decarbonization together

The topic of decarbonization affects us all and is redefining our world. It is not only an ecological imperative, but also an accelerator of innovation. The resulting change is leading to new products and technologies that require modern approaches to quality assurance from product development to manufacturing. Zeiss offers advanced metrology solutions to support industrial companies in this transformation in the best possible way.

Enabling product innovations

Decarbonization is a global trend that is driving innovation in continuously evolving markets, such as e-mobility, aerospace and power generation. New products and technologies such as batteries, e-motors and electrolyzers require high-precision metrology to ensure longevity and reliable performance.

From material testing and product development to production and maintenance, Zeiss offers a comprehensive portfolio of state-of-the-art metrology solutions. Through reliable quality assurance, Zeiss industrial metrology helps customers drive innovation to reduce global emissions that can adapt to ever-changing requirements.

Increase product efficiency

Increase product efficiency

Efficiency improvements play a crucial role in reducing the global carbon footprint. To increase product efficiency, accurate measurement of individual parts using high-precision metrology with tight tolerances is essential.

For example, hundreds of hairpins inside a stator must meet the strictest dimensional requirements to ensure efficient performance of electric motors. Similarly, the optimal operation of an aircraft engine depends heavily on the quality inspection of thousands of compressor blades. Zeiss supports customers with a comprehensive hardware and software portfolio that offers different measurement technologies for each individual production step. As a result, Zeiss solutions contribute to longer product life cycles, longer battery ranges, lower fuel consumption and further resource savings.

Hall 5, Stand 5405

www.zeiss.de/messtechnik