Horsch’s bright red agricultural machinery is becoming increasingly common on Brazil’s fields, as the German manufacturer’s share of the Brazilian agricultural machinery market continues to grow. The machine parts are painted at the company’s own site in Curitiba. There, up to 65 tons of steel per week run through the still young jumbo coating system from Meeh. It is modular and designed with sufficient expansion options, making it ideally suited to Horsch’s dynamic development in South America.

Meeh

Every tenth precision air seeder in Brazilian fields already bears the characteristic red of the German company Horsch Maschinen GmbH. The internationally positioned family business from Schwandorf has also had a presence in South America since 2015. Initially, the company was still working in rented premises in Brazil, but in 2020 Horsch invested in its own land and built the current company headquarters in Curitiba in the state of Paraná.

The buildings, which will be completed in 2023, will also allow Horsch to expand its vertical range of manufacture and relocate all work areas to its own premises. After all, there is no shortage of space. “The actively used site here in Curitiba alone covers 160,000 square meters, 25,000 of which are under roof. A further 240,000 square meters are available to us in the form of open spaces and meadows right next door,” says Mathias Boldt, Production Manager at Horsch do Brasil, describing the site.

They are therefore installing an impressive coating system in the extensive factory halls as part of the new building. Boldt is supported in the planning by experienced colleagues from Germany, where Horsch has been successfully operating several painting centers for years. For the ambitious project in Brazil, however, the planning team opted for a new partner and awarded the contract to Meeh Pulverbeschichtungs- und Staubfilteranlagen GmbH from the Swabian town of Wimsheim.

Special cross-conveyor technology makes the difference

Meeh

The fact that the agricultural engineers are even aware of the Swabians is probably due to Horsch’s good business situation and the special Meeh conveyor technology. At the time of the plans for Brazil, the busy Horsch painting center in Ronnenburg was placing orders with external contract coaters who work with jumbo coating systems. “This is where we first saw Meeh’s cross conveyor technology and became curious,” says Roland Schönleber, Production Manager at the main plant in Schwandorf, about the start of the partnership. In addition to the innovative technology and the variable system modules, the competent people from Wimsheim even have experience in Brazil. The joint development was completed quickly and the customized system was set up on site using lead assembly. “That was important to us,” says Schönleber. This meant that the Brazilian fitters were already familiar with the plant technology.

Convincing variability of the system

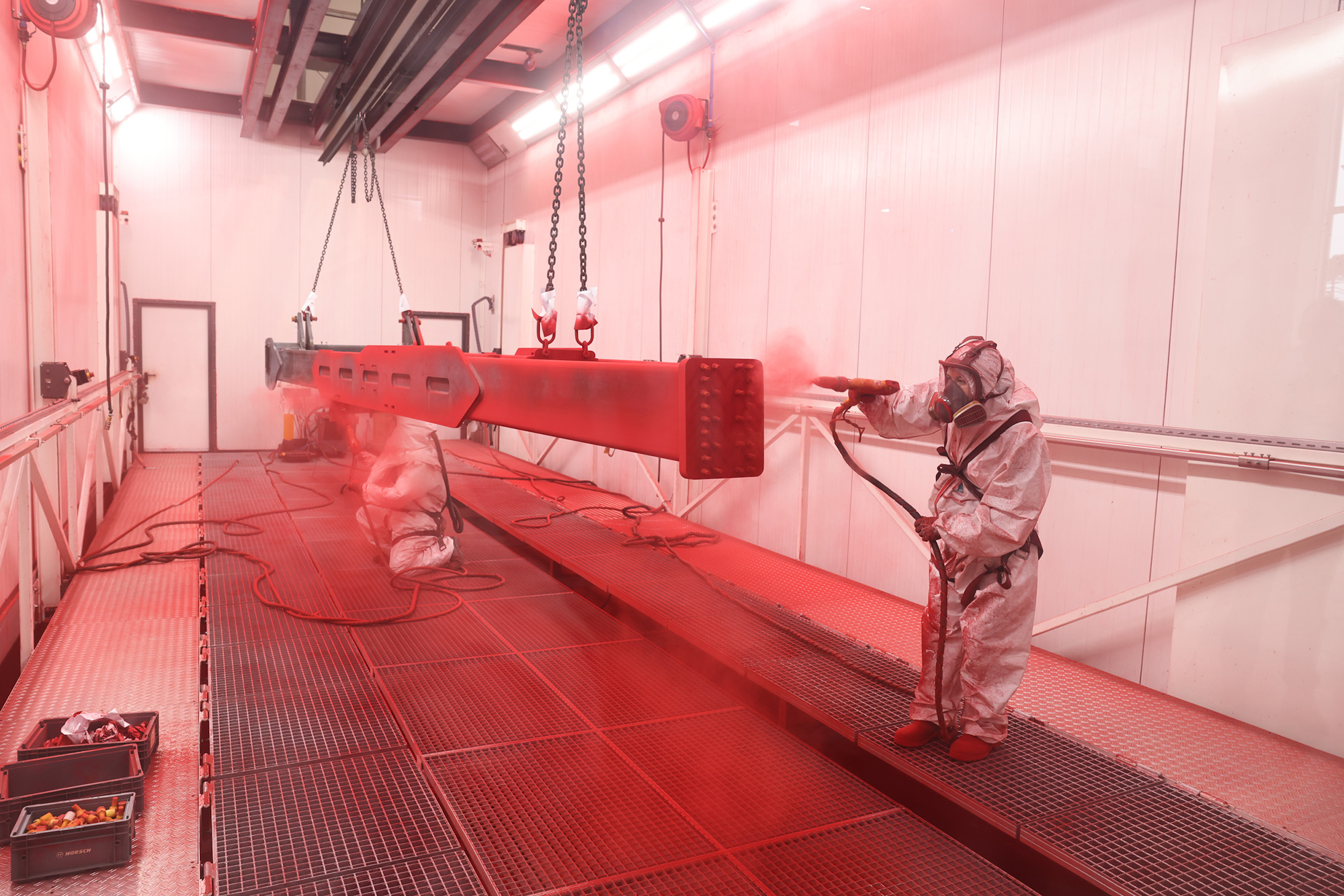

The coating system in Curitiba was initially designed primarily for manual operation and, like all Jumbo Coat systems, has a modular structure. It currently houses five process booths and a spacious loading station with a parking lot, which are connected via traverses and two electric cross-moving platforms with integrated lifting and lowering stations. The individual modules are arranged in two parallel rows according to the work processes. This keeps walking distances short despite the generous floor space.

Meeh

The choice of work booths was also planned pragmatically. Although Horsch only paints steel in Brazil, they require different processing methods due to the variety of products. As a result, there is a blasting and washing booth for pre-treatment and a choice between powder and wet paint for coating. “We can coat all machine parts in the system, regardless of their properties, geometry or size. And with the best results,” says Boldt, appreciating the versatility of the system. The differences in size are immense. From handy small parts to large steel frames, everything runs through the same chambers. The limit is 12 x 3 x 3 m and three tons per workpiece carrier.

Pre-treatment zone and powder booth work in a circuit

Despite the largely manual operation, Horsch also focuses on efficiency and sustainability in Brazil. To this end, Meeh has equipped the blasting, washing and powder booths with a recovery system. Washing is carried out accordingly in recirculation mode and, depending on the number and width of the workpieces, either manually or with the help of the two automatic spray rims.

Meeh

The parts go through a total of three rinsing cycles, during which they are degreased, phosphated and rinsed with demineralized water. To increase the service life of the media, Meeh cascades the baths and produces the necessary demineralized water using a water treatment system and a vacuum evaporator. The amount of fresh water required is therefore kept to a minimum. Right next to the washing cabin are two ovens heated indirectly by gas. Both washed and powder-sprayed workpieces dry in them, sometimes simultaneously.

“Depending on its load, each traverse is allocated an individual drying time, the expiry of which is indicated acoustically and visually,” Ulrich Meeh explains his system. In the powder spray booth, Horsch only processes red paint, which, together with the return of excess powder, also contributes to the efficiency of the system. This is because color changes are usually associated with higher paint, cleaning and time expenditure. Horsch appropriately paints everything in gray in the wet paint area and uses a highly reactive, fast-drying paint system. This means that the parts are already dust-dry as soon as they leave the wet paint booth and can be stored in the buffer area until the paint is completely dry.

Meeh

Practical components make work easier

In pre-treatment and powder coating, Meeh has installed several special features that make it much easier to handle workpieces of different sizes. For example, the lifting platforms in the cabs can be moved independently of each other so that the working height can be individually adapted to the respective requirements. In addition, two automated swivel devices originally developed by Horsch have been installed especially for the large tanks of the Maestro seed drills. With their help, the employees turn the heavy hoppers until the opening is in a horizontal position. This makes it much easier to process the inside of the tanks.

Planned with foresight

When designing the facility, the team took future expansion into account and provided open areas for additional process cabins and parking spaces. “The market situation and capacity utilization of the plant are showing us sooner than expected how sensible our forward-looking planning was,” says Boldt. This year, the Brazilians are planning to automate the cross-travel platforms together with Meeh, and a second powder booth will relieve the wet paint area in the foreseeable future. Thanks to the practical modular design, the cost of these measures remains extremely low. Schönleber is also completely satisfied with the plant and the process in Brazil. “The cooperation is excellent, which is why we have already earmarked Meeh for further international plant projects.”

Meeh

Facts & Figures

Meeh Pulverbeschichtungs- und Staubfilteranlagen GmbH was founded in 1992 by Ulrich Meeh and is a Swabian family business in the best sense of the word. With around 70 employees, the company designs, manufactures, assembles and commissions customized, individual powder coating systems. The modular Jumbo-Coat and Flex-i-Coat systems are used worldwide in almost all major industrial sectors. Users can also coat and paint large parts with dimensions of up to 16,000 x 3000 x 4000 mm in the powder coating and painting systems.

Web:

Simone Frick, specialist journalist from Lichtenwald

jumbo-coat.com