The 100th UMS flatness control system is used by Werk Redex worldwide to produce thin and ultra-thin precision rolled strips of the highest quality.

© Redex

Arinox, a company of the Arvedi Group, is currently the only Italian manufacturer of stainless precision rolled steel. The Tredi plant in the province of Genoa produces thin and extra-thin precision rolled strip up to 1,570 mm wide and 0.05 mm thick.

The plant in Sestri Levante has an annual capacity of over 65,000 tons and state-of-the-art industrial facilities for the production of precision rolled strip in stainless steel, nickel alloys and titanium for the automotive, precision mechanics, plant engineering, components, biomedical and electronics industries.

The stainless steel precision strip sector is particularly important as it is a high-tech product. Its manufacture requires state-of-the-art machinery and exceptional technical expertise in production processes. Arinox has always worked actively with its strategic suppliers, such as Redex for straightening, to develop new solutions. These allow the company to differentiate itself in the market by offering products of high quality and precision.

© Redex

Flatness is a guarantee of quality

In order to be able to offer high-quality rolled products, the material must be as flat as possible. The flatter a strip is, the easier it is to slit without suffering deformation. The rolling process and subsequent annealing improve the mechanical properties of the strip, making it more suitable for precision slitting. At the Sestri Levante plant, Arinox has always successfully used Redex solutions for stretch leveling.

Mauro Moretti, Technical Director of Arinox, explains: “Since our first narrow strip rolling mill, we have been using the straightening technology of Ungerer, a company that later merged with Redex. In view of the excellent results, we have once again opted for Redex’s straightening solutions when investing in rolling mills with a width of 1,260 mm and, more recently, 1,575 mm. We continue to work very successfully with this company and greatly appreciate their expertise and availability.”

The tensile straightening process for rolled metal strips is primarily used to correct the shape of the material. To do this, it is bent by small, calibrated deformations under the effect of an externally applied tension. The result is a controlled elongation that makes the short fibers of the belt the same length as the longer ones. This creates a flat belt and relieves internal tension.

© Redex

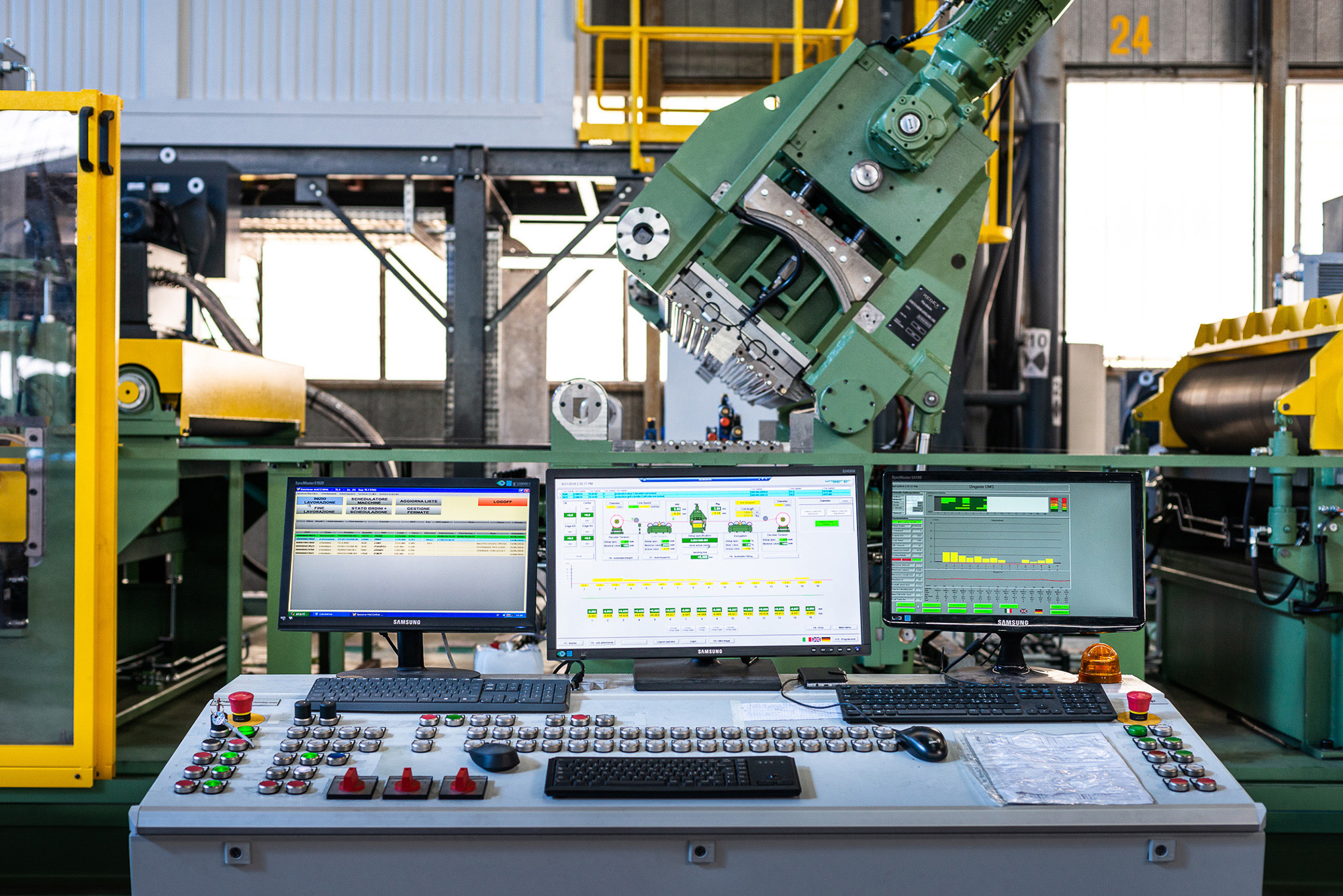

The 100th EMS flatness control system

The measuring and control system for flatness plays a very important role in ensuring that the stretch leveling system can guarantee the required precision. The UMS (unflatness measuring system) from Redex has therefore now been further developed into the even more sophisticated UMS Pro (Proactive) version. It is recognized worldwide for its accuracy and effectiveness. The 100th system of this type has been installed at Arinox, helping to ensure flatness within the very strict tolerance limits required by the Ligurian company’s customers.

Mauro Moretti comments: “Using an ‘intelligent’ tension roller equipped with piezoelectric sensors, the UMS Pro system corrects the position of the wedges in the straightening machine and the tension force in real time, without the operator having to intervene manually. This ensures a high degree of uniformity in product quality.”

However, research and testing of innovative solutions continues at Arinox – in keeping with the tradition of the parent company Arvedi Group. A new type of tension roller was recently tested in collaboration with Redex. This has proven to be particularly suitable for further improving the straightening process – especially when processing primary materials. This is rolled stainless steel without annealing, which is often used in the automotive industry or in the manufacture of springs.

Mauro Moretti concludes: “Machines are never perfect. People need to know how to control and improve them. In Redex, we have found a partner with whom we can continue on our path of continuous improvement.”

Background

The Redex Group, with subsidiaries in France and Germany, has 450 employees, including more than 100 engineers. The group sells its products worldwide and specializes in equipment for the metal industry and components for machine tools. The Redex Group’s product portfolio includes metal strip processing lines, rolling mills and precision gears. The estimated turnover for 2025 is around 100 million

Web:

www.redex-group.com